By quanyu lee

2025-01-14 01:13:37

Customizable Flat Ribbon Cable Knowledge Sharing

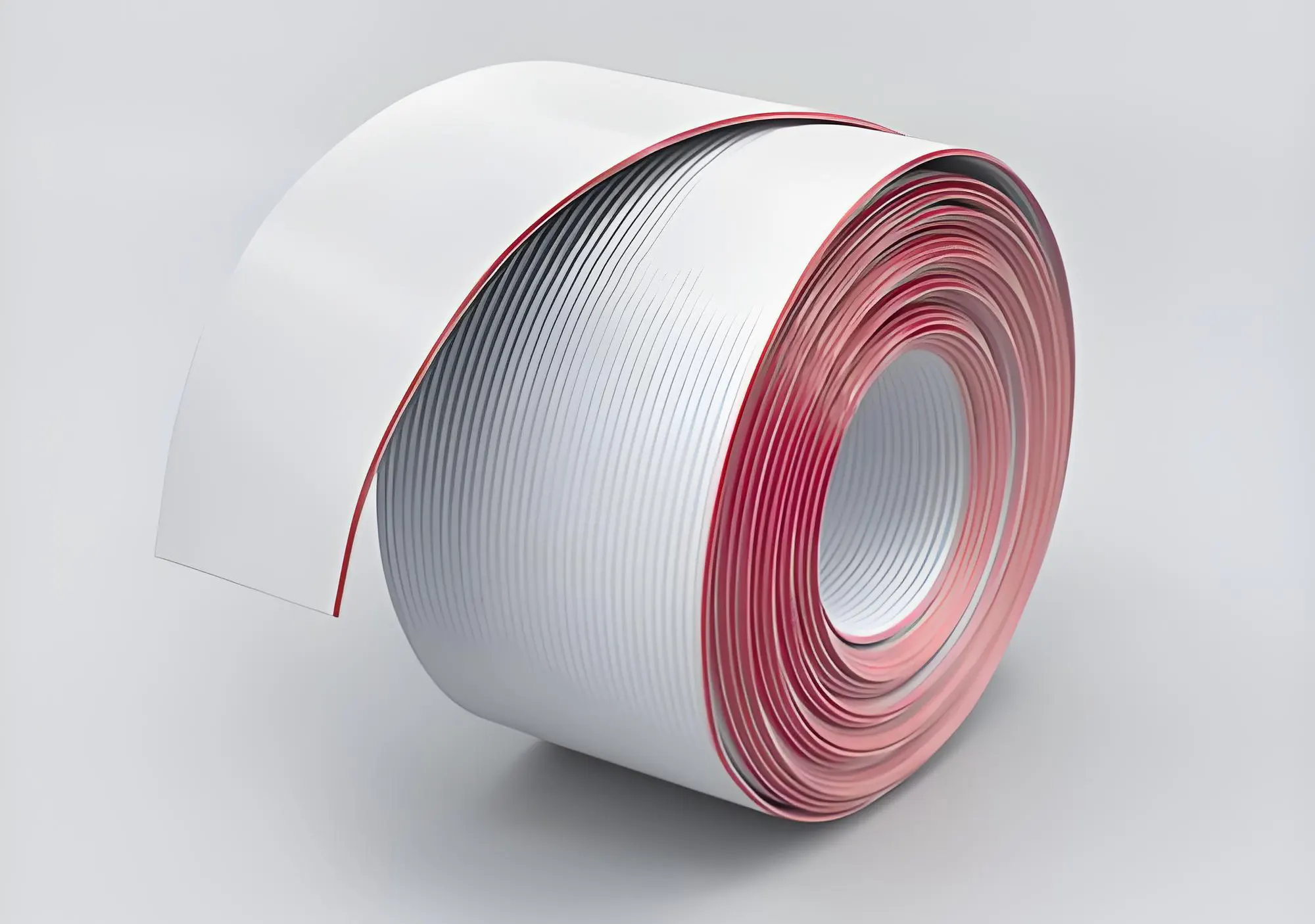

With the continuous development of electronic devices, the automotive industry, and industrial automation, the requirements for cables are becoming increasingly demanding. Compared to traditional round cables, customizable flat ribbon cables are becoming an ideal choice for precision equipment and high-performance applications due to their compact structure, flexible routing, and support for functional integration. This article will provide an in-depth introduction to the definition of ribbon cables, their application value, and the advantages of customization, as well as explore how to choose the right supplier.

1. What is a customizable flat ribbon cable?

Customizable flat ribbon cables are cables composed of multiple parallel conductors that can be customized to meet varying electrical performance, space constraints, and environmental requirements. They are commonly used in computers, printers, medical devices, automobiles, industrial robots, and other fields. Customization can include conductor material, insulation material, wire diameter, interface method, and functional module integration.

2. Definition and Basic Concepts of Ribbon Cable

Many people have misunderstandings about "ribbon cable" and easily confuse it with "ribbon cable" and "flat cable".

| concept | Correct understanding | Common misunderstandings |

| Ribbon Cable | Multi-core conductors are arranged in parallel to form a flat structure | Equivalent to all flat cables |

| Flat Cable | Generally refers to cables with flat structures, including ribbon cables | Completely different from ribbon cable |

| Flexible Cable (FFC/FPC) | Flexible printed cables, mostly used inside electronic devices | Synonymous with ribbon cable |

3. Advantages of Flat Ribbon Cable Customization

- Space Saving: More compact wiring in limited installation spaces.

- Efficient Transmission: Parallel arrangement reduces electromagnetic interference and improves signal integrity.

- Flexible Customization: Length, connector, shielding, and other features can be configured to meet device requirements.

- Easy Installation and Maintenance: The integrated structure reduces connection errors.

4. Advantages of Customized Flat Ribbon Cables

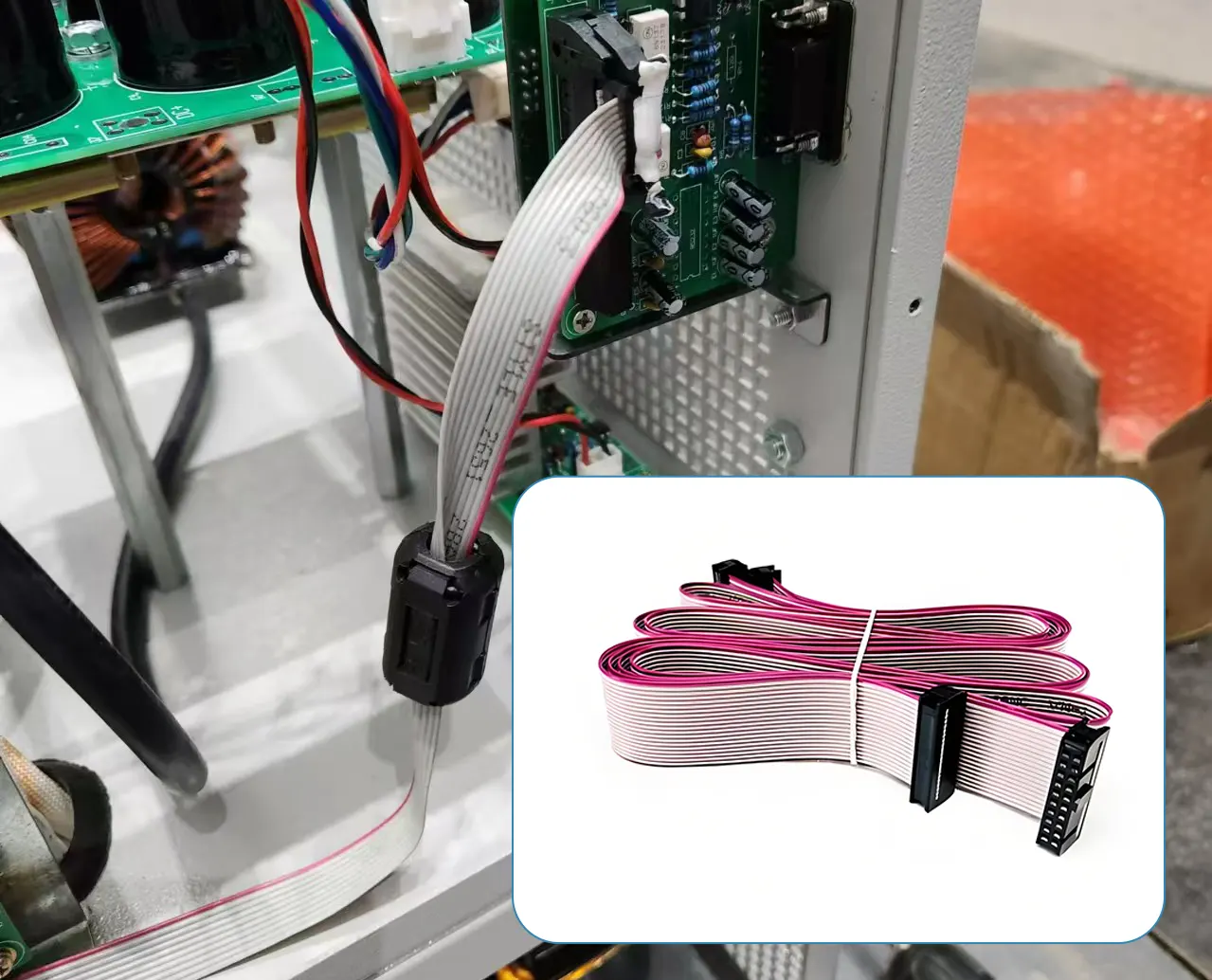

Compared with universal standard wiring harnesses, customized ribbon cables demonstrate more significant value in practical applications. They can achieve powerful functional integration, efficiently combining power lines, signal lines, and shielded lines in the same wiring harness without the need for additional split layout; at the same time, by reducing the design of redundant connectors, the risk of poor contact is greatly reduced, further improving the reliability of the overall connection. In addition, customized ribbon cables also have excellent high-temperature resistance and chemical corrosion resistance, and can easily adapt to various harsh working environments, such as the industry and automobile, to ensure stable operation. More importantly, it can accurately meet the special needs of the equipment. For example, for medical equipment, it can strictly meet the corresponding medical-grade certification standards to ensure safety and compliance in use.

Kaweei's wire harness customization factory boasts extensive technical expertise and practical experience in the field of customized ribbon cables. We offer tailored OEM/ODM solutions tailored to specific customer needs. We support high-volume custom orders with rapid delivery, effectively shortening production cycles and improving project efficiency.

5. Flat Ribbon Cable Material Selection and Accessories

The selection of materials and accessories for flat ribbon cables must be precisely matched to the actual application requirements. Copper and tinned copper are commonly used conductors, meeting the conductivity requirements of most scenarios. Silver-plated copper can be used for some high-frequency applications to ensure signal transmission performance. In terms of insulation materials, PVC, polyester, and fluoroplastics are mainstream options, and the specific selection should be based on the temperature resistance, flexibility, and electrical performance requirements of the cable's operating environment. Shielding layers are often made of aluminum foil or braided shielding, whose core function is to effectively reduce external electromagnetic interference and ensure the stability of cable signal transmission. Common connectors include IDC connectors and board-to-board interfaces, which can adapt to the connection requirements of different devices and ensure a reliable connection between cables and devices.

6. Flat Ribbon Cable Quality and Certification

In precision electronics and industrial applications of flat ribbon cables, various authoritative certifications are crucial for ensuring product quality and regulatory compliance. UL certification effectively verifies the safety and flame-retardant properties of cables, providing a core guarantee for safe use. RoHS and REACH certifications focus on environmental protection requirements, strictly restricting the use of hazardous substances and ensuring product compliance with mainstream global environmental standards. ISO9001 and IATF16949 certifications address production management, standardize factory quality systems, and ensure consistent quality throughout the entire production process. CE and CCC certifications, crucial for regional market access, ensure compliance with market regulations in Europe and China, respectively, meeting the specific usage and sales requirements of specific regions.

7. How to choose a supplier?

When selecting a suitable ribbon cable supplier, four key considerations should be considered: First, experience and case studies: focus on project experience and successful case studies in target industries (such as industrial, medical, and automotive), ensuring a deep understanding of industry needs. Second, engineering capabilities: determine whether the supplier can provide flexible custom design support, integrating multiple functions such as power cables, signal cables, and shielded cables to meet device-specific requirements. Third, delivery capabilities: focus on stable and controllable lead times, and whether the supplier can meet the full cycle time requirements, from rapid prototyping and verification to mass production. Fourth, OEM/ODM services: confirm whether the supplier possesses mature branded production capabilities and can complete customized production according to customer specifications and brand logos.

For example, Kaweei, a custom wire harness manufacturer, has many years of experience in customizing ribbon cables. Leveraging advanced production equipment and a rigorous end-to-end quality control system, the supplier can accurately respond to core requirements such as custom design and functional integration, while ensuring stable delivery and rapid prototyping, providing highly reliable custom wire harness solutions to global customers.

8. FAQs Frequently Asked Questions About Customizable Flat Ribbon Cables

Q1: What is the minimum bend radius for customizable flat ribbon cables?

A: It depends on the material and construction, but is generally 6–10 times the cable thickness.

Q2: Can power and signal be transmitted simultaneously through a single ribbon cable?

A: Yes, with proper layout and shielding design, interference can be reduced.

Q3: What is the lead time for customization?

A: Samples typically take 2–3 weeks, and mass production depends on the complexity of the order.

Q4: Does Kaweei support small-batch customization?

A: Yes, we can meet customer needs, from small trial runs to large-scale production.