By quanyu lee

2025-10-17 10:40:30

IDC Ribbon Cable Guide: Flat Data Channels Connecting the World

In modern electronics and industrial equipment, IDC ribbon cables have become one of the most common and important connectors. Whether used in computer motherboards, printers, industrial control systems, or automated test equipment, IDC cables play a key role in data and signal transmission. This article will provide an in-depth understanding of this essential yet indispensable cable product, focusing on its structural design, application scenarios, selection considerations, and future development trends.

1. What is an IDC Ribbon Cable?

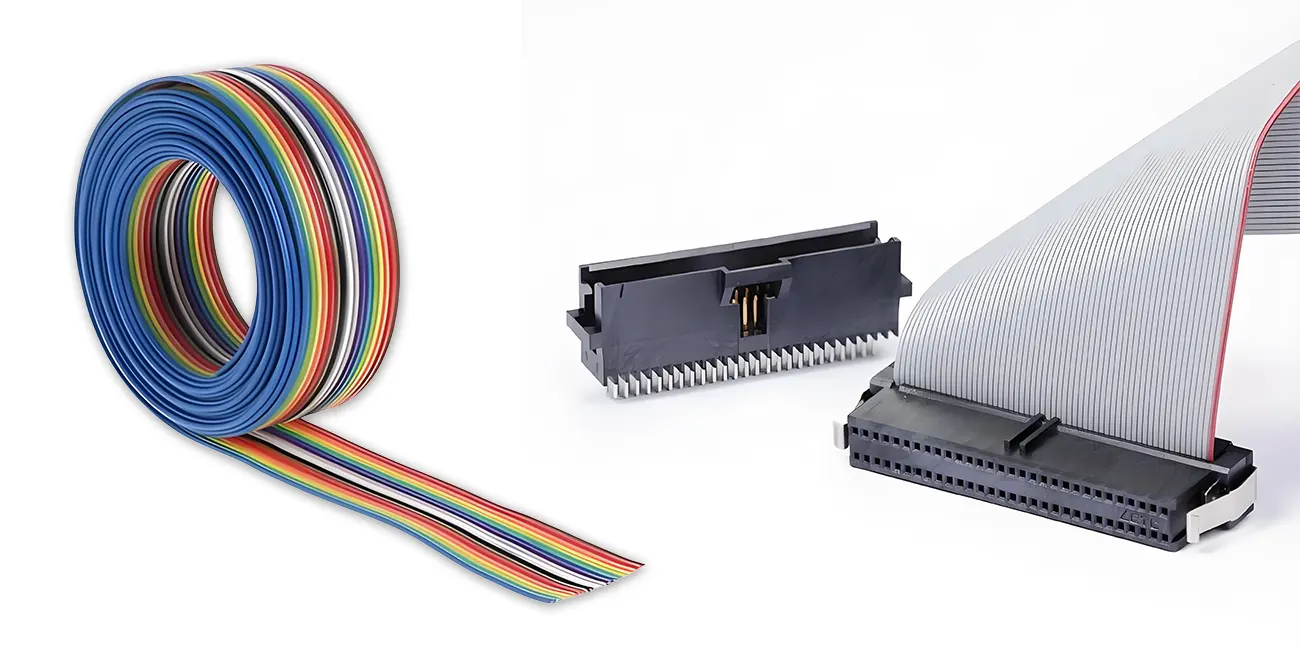

IDC cables are wrapped, multi-core cables consisting of multiple insulated conductors arranged side-by-side. They are often used with IDC connectors, achieving fast and stable multi-core connections through crimping.

IDC, which stands for "Insulation Displacement Connector," is a connection technology that allows for direct crimping of conductors by simply stripping the wire. This wraparound cable allows for quick connections, significantly improving production efficiency and connection reliability. It is widely used in consumer electronics, industrial automation, automotive electronics, and other fields, significantly improving production efficiency and connection reliability.

2. Structure and characteristics of IDC cable

IDC cables feature a sophisticated design and are primarily composed of the following components:

- Conductor: Mostly tinned copper wire, offering excellent conductivity and oxidation resistance.

- Insulation: Mostly made of PVC, PE, or TPE, offering flexibility and heat resistance.

- Flat structure: The spacing between each conductor is fixed (e.g., 1.27mm, 2.54mm), facilitating standardized connections and automated installation.

Product Type and Price

- Pitch Specifications: Common 1.27mm, 2.0mm, and 2.54mm pitches, supporting 6P-64P wire counts.

- Material Features: Primarily tinned copper core, UL2651 fireproof ash cable, heat-resistant, and suitable for displays, new energy equipment, and other applications.

IDC cables not only offer the advantages of multi-core parallel transmission and minimal signal interference, but also enable high-speed data communication. They are compatible with a variety of standard interfaces (such as 2.54mm pitch IDC connectors) and support batch assembly, making them suitable for automated production lines.

3. Materials and manufacturing processes

- Conductor: High-purity oxygen-free copper (OFHC) or tinned copper wire is typically used. The stranded structure improves flex resistance (for example, a 7×0.05mm stranded wire has a flex life of over 500,000 cycles).

- Insulation Materials: Common insulation materials include PVC (-20°C to 80°C), PE (excellent dielectric properties), PTFE (-200°C to 260°C), and PI (-269°C to 400°C). PI is often used in demanding applications such as medical and military applications.

- Manufacturing Precision: The fully automated production line achieves a machining accuracy of ±0.01mm, ensuring stable signal transmission.

4. Connector Types and Interface Standards

- IDC connectors for flat cables: Commonly found inside computers, such as connecting hard drives to motherboards, support pitches of 0.05 inches (1.27mm) and 0.1 inches (2.54mm).

- Wire-to-board IDC connectors: Used to connect single-core cables to PCBs, suitable for home appliances or industrial control panels.

- Industrial circular connectors, such as the M12 IDC, support field termination and IP67 protection, and are widely used in sensors and Ethernet networks in industrial automation.

5. Typical Applications of IDC Ribbon Cables

IDC Ribbon Cables are widely used in the following areas:

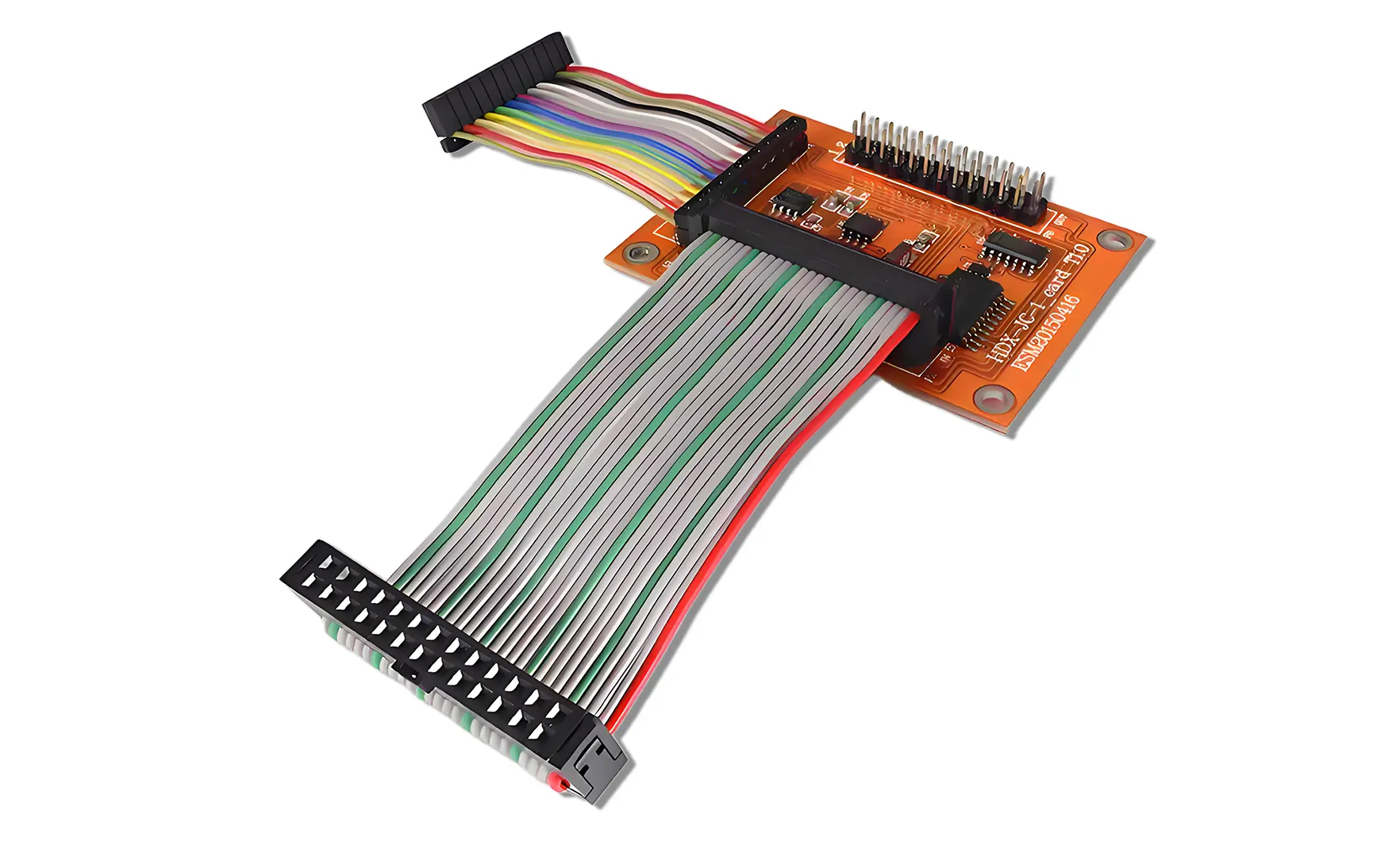

- Computers and communications equipment: Used for data transmission between the motherboard and expansion cards and hard drives.

- Industrial automation systems: Used for signal connections between PLC controllers, sensors, and test equipment.

- Consumer electronics: Used for internal circuit connections in printers, scanners, and home appliances.

- Medical equipment and measuring instruments: Used for signal acquisition and modular assembly of precision instruments.

With its standardized interface and high assembly efficiency, IDC ribbon cables have become an irreplaceable connectivity solution in electronics manufacturing.

6. How to Choose the Right IDC Cable?

When selecting a cable, consider the following:

- Number of Cores and Pitch: Choose common specifications based on the connector type (e.g., 10-core, 20-core, or 40-core, with a pitch of 1.27mm or 2.54mm).

- Insulation Material: For high-temperature environments, choose heat-resistant PVC or polyester.

- Flexibility and Bendability: For space-constrained equipment, choose a cable with high flexibility and good bending resistance.

- Shielding Performance: For high-frequency signals or noise-sensitive environments, a shielded IDC cable is recommended.

Professional manufacturers like Kaweei offer custom cable harness solutions.

They can provide customized IDC cable solutions with varying lengths, specifications, and termination methods, ensuring product compatibility and stability.

7. Future Development Trends

With the miniaturization and high-speed advancements in electronic devices, IDC ribbon cables are also evolving towards the following:

- Finally, smaller pitches and higher-density designs

- Improved flexibility and high-temperature resistance

- Enhanced compatibility with automated assembly

- Environmentally friendly materials and full compliance with RoHS standards

This means that future IDC ribbon cables must not only provide stable connections, but also fast and intelligent connections.

8. FAQ: Things you might want to know about IDC Ribbon Cables

Q1: What's the difference between IDC cables and FPC cables?

A: IDC cables typically use multi-core copper conductors and IDC connectors, suitable for medium- and low-speed signal connections. FPC cables, on the other hand, use flexible printed circuits, suitable for high-density connections in thin and lightweight electronic devices.

Q2: Are IDC cables waterproof or heat-resistant?

A: Standard IDC cables are not waterproof, but they can be protected with a jacket or special materials. For high-temperature applications, choose heat-resistant PVC or polyester.

Q3: Can IDC cables with different lengths and connectors be customized?

A: Yes. Custom manufacturers like WIRE HARNESS ASSEMBLY can provide IDC cable solutions with specific lengths, core counts, spacing, and connector standards based on customer designs.