By quanyu lee

2025-09-16 10:48:25

A comprehensive guide to BMS cables: types, functions, applications, and custom options

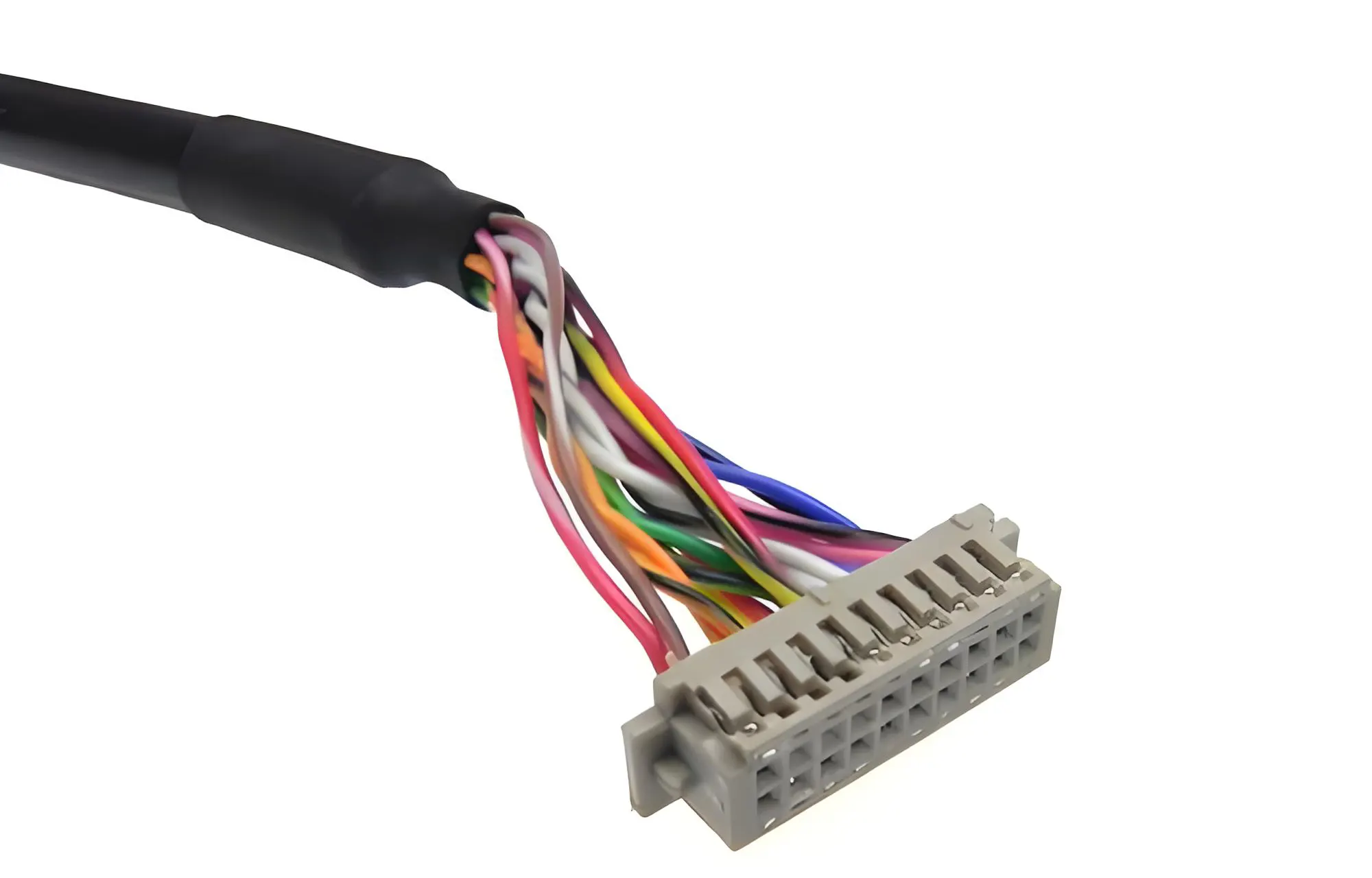

With the rapid development of new energy and electric vehicles, the Battery Management System (BMS) has become crucial for ensuring battery safety and performance. As a crucial component of a BMS, BMS cables, along with BMS connectors and terminals, form the pathway for battery data and energy transmission. This article will delve into the concepts, functions, types, and applications of BMS cables, providing a comprehensive guide for selecting the right cable.

1. What is a BMS connector?

BMS connectors are key components in the battery management system, connecting battery cells, BMS cables, and control units. Common types include:

- 2-core connectors: Used for basic power supply or low-current signal transmission.

- Multi-core connectors (such as 10-core and 20-core connectors): Suitable for complex functions such as voltage acquisition and temperature monitoring.

- High-voltage BMS connectors: Widely used in electric vehicle wiring harnesses and energy storage systems, ensuring safety under high currents.

These connectors are typically required to comply with IEC standards and be UL certified to ensure their safety and reliability.

High-quality BMS connectors usually have anti-loosening, waterproof, fireproof, and other features to ensure stable operation of the system.

2. What is a BMS cable?

BMS cables are specialized cables used in Battery Management Systems (BMS). Their primary function is to transmit voltage, current, and temperature signals from battery cells and to perform control and communication tasks. Unlike ordinary cables, BMS cables are highly flexible, heat-resistant, flame-retardant, and anti-interference. They are a core component of electric vehicle wiring harnesses and energy storage system cables.

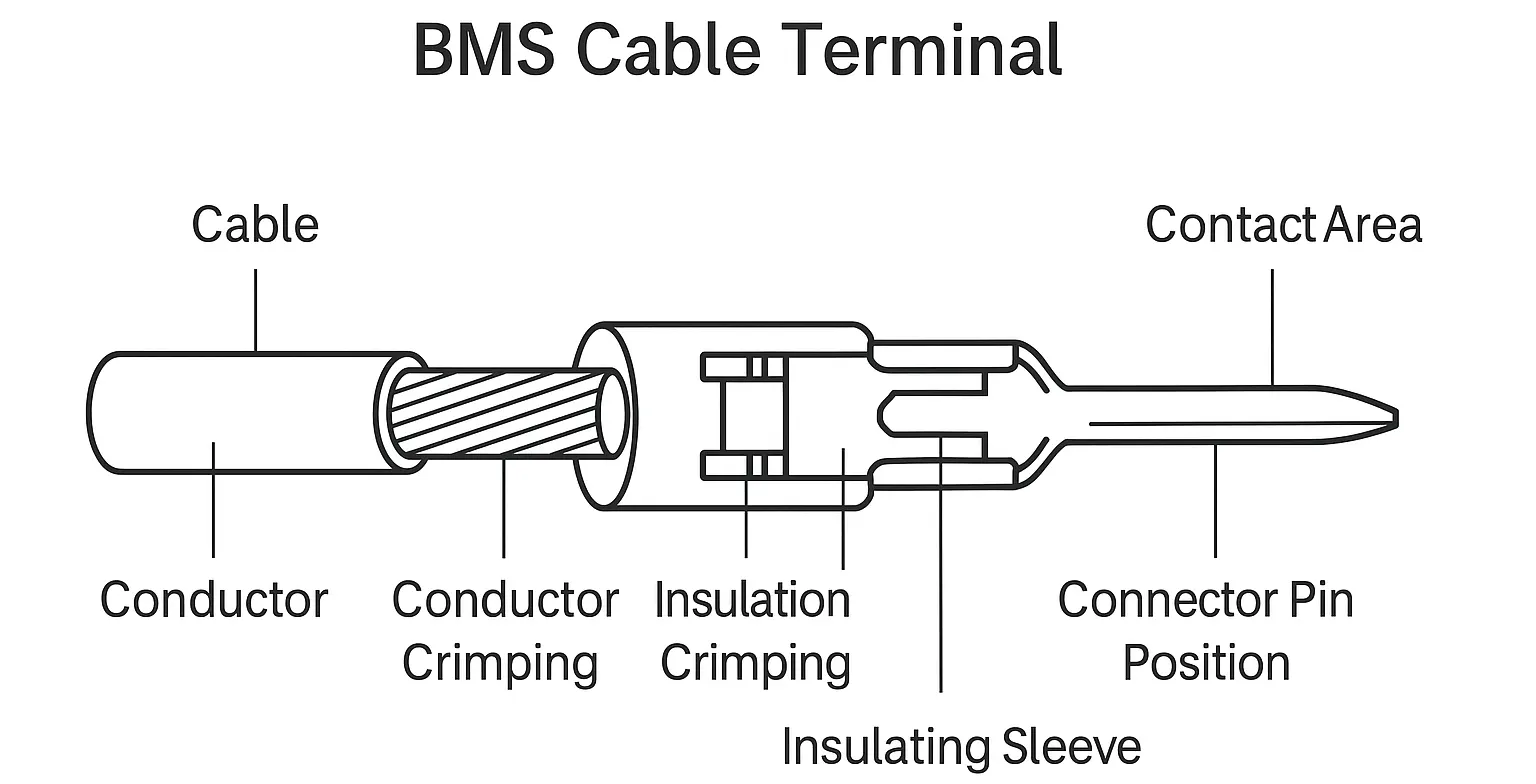

3. What is a BMS cable terminal?

The BMS cable terminal is the interface between the BMS cable and the BMS connector, PCB control board, or battery module. Its quality and design directly determine the stability of the signal and power transmission. The terminal is not only a key part of the electrical connection, but also an important part of mechanical fixation and protection.

Common BMS cable terminal types

1. Crimp Terminal

- This is the most common terminal type. A crimping tool securely connects the terminal to the cable's copper conductor.

- Advantages: Excellent conductivity, high mechanical strength, and suitable for mass production.

2. Solder Terminals

- Solder the cable directly to a metal terminal or PCB.

- Advantages: High reliability, suitable for applications requiring permanent mounting.

3. Plug-in Terminals

- The cable end features a plug that allows for quick insertion and removal from the female connector.

- Advantages: Easy maintenance and replacement, commonly used for testing or assembling battery modules.

4. Insulation Displacement Terminals (IDTs)

- Specially designed metal blades directly pierce the cable insulation and establish contact with the conductor.

- Advantages: Eliminates the need for wire stripping, improving assembly efficiency. Commonly used for multi-core signal acquisition.

Key performance requirements for BMS cable terminations

- Conductive Performance: Low contact resistance ensures efficient signal and current transmission.

- Mechanical Strength: Vibration and pull-out resistance prevent loosening in electric vehicles and energy storage environments.

- Corrosion Resistance: Tin-plated or silver-plated copper is often used to prevent oxidation.

- High-Temperature Resistance and Flame Retardancy: Ensures stable operation in the high-temperature environment of the battery compartment.

- Compatibility: Requires compatibility with BMS connectors and cable insulation materials.

Important Roles in the System

- Ensures complete transmission of signals such as voltage, current, and temperature to the BMS main control unit.

- Reduces energy loss and heat generation, improving system energy efficiency.

- Enhances system reliability and adaptability to complex operating conditions such as vibration and humidity.

- Supports modularity and maintainability, with plug-in terminals facilitating quick module replacement.

4. BMS Cable Functions

- Voltage and current detection: Real-time monitoring of battery status.

- Temperature acquisition: Prevents battery overheating or overcooling.

- Balance control: Ensures energy balance between battery cells.

- Signal transmission: Connects the inverter, charger, and control unit to ensure coordinated system operation.

5. Main Types of BMS Cables

- High-voltage BMS cables: used in electric vehicle power systems.

- Signal acquisition cables: used to transmit data such as temperature and voltage.

- Shielded BMS cables: resist electromagnetic interference and ensure data accuracy.

- Flexible cables: adapted to withstand vehicle vibration and frequent bending.

6. What are the application areas for BMS cables?

- Electric vehicle wiring harnesses (EV, HEV, PHEV)

- Energy storage system cables (ESS)

- Photovoltaic inverter systems

- Electric two-wheelers and electric boats

- Industrial UPS and backup power supplies

7. Inverter BMS Cable

In photovoltaic energy storage and electric vehicle applications, the inverter requires real-time communication with the BMS system via a BMS cable. This cable transmits battery operating data, enabling the inverter to adjust its charging and discharging strategies based on battery status, thereby improving energy efficiency and system safety.

8. How to choose the right BMS cable?

When selecting a BMS cable, consider the following:

- Complies with IEEE standards for electrical safety

- Voltage and current ratings

- Operating environment (temperature, humidity, vibration)

- Shielding and insulation performance

- Compatibility with BMS connectors and terminals

For customers with special needs, we recommend Kaweei, a custom wiring harness manufacturer. As a professional supplier, Kaweei can provide customized BMS cables and electric vehicle wiring harness solutions based on different application scenarios, ensuring the system remains stable and reliable even in high-intensity applications.

9. FAQs: Frequently Asked Questions About BMS Cables

Q1: What is the difference between BMS cables and ordinary cables?

A: BMS cables are heat-resistant, flame-retardant, and anti-interference, making them more suitable for the complex environment of battery management.

Q2: Can BMS cables be used in high-voltage systems?

A: Yes, but you must select standard high-voltage BMS cables.

Q3: Can BMS cables be customized?

A: Yes, our factory can customize the number of cores, shielding method, terminal type, and length according to customer requirements.

Q4: What is the lifespan of BMS cables?

A: Under normal use, they can operate stably for a long time. However, if insulation aging or poor contact occurs, they should be replaced promptly.

10. Summary

BMS cables, as a crucial component of the battery management system, directly determine the safety and reliability of batteries. The design of BMS connectors, terminals, and the entire cable must meet high reliability and safety standards. With the rapid development of the new energy industry, demand for BMS cables and energy storage system cables will continue to grow.