By quanyu lee

2025-07-30 06:52:48

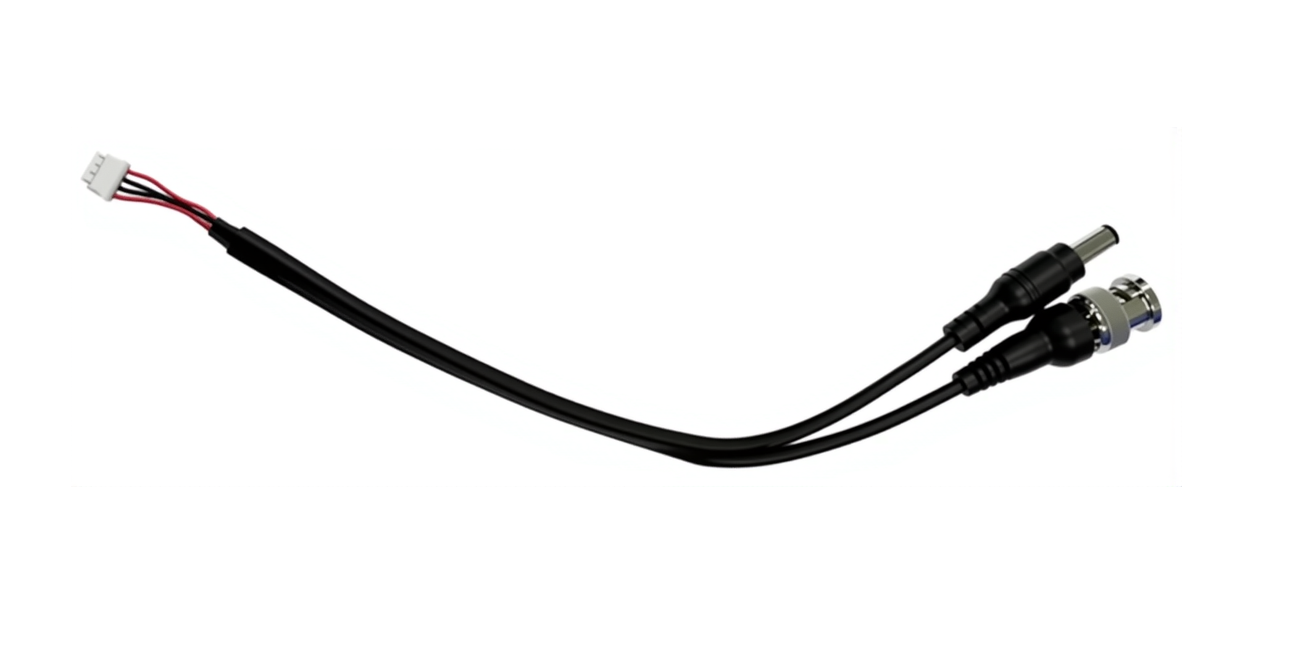

BNC Male to DC Plug Cable Harness

The BNC male to DC plug cable harness is widely used in signal transmission applications, particularly for video, audio, and RF communication. This guide covers the materials, structure, production, and testing process to ensure high performance and durability in industrial applications.

BNC and DC Plug Overview

BNC connectors are designed for coaxial cables and feature a quick-release snap-on mechanism. BNC male connectors contain a center pin and are commonly used for RF signal transmission, such as in CCTV, broadcasting, and test equipment. DC plug connectors (5.5 x 2.1 mm) are the standard for low-voltage power transmission. This BNC-to-DC cable assembly ensures stable signal and power integration.

Cable Harness Materials

Wire Type: UL2464 26AWG x 2C, ensuring durability and electrical safety.

Connectors: High-quality BNC male connector (75 ohm impedance) + DC plug, with a plug and unplug life of ≥ 500 cycles.

Heat Shrnk Tubing: 300V withstand voltage heat shrink tubing, insulation resistance ≥ 100MΩ.

Injection Molding: Double-layer PVC (inner film + outer mold), with an IP54 waterproof and dustproof rating.

Wire Harness Production Process

Wire Cutting and Stripping: Precise cutting (±0.5mm), clean end faces for easy soldering/crimping.

Injection Molding: Low-pressure injection molding, double-layer sealing, enhances durability and protection.

Heat Shrink Tubing: UV adhesive is used for proper sealing and reinforcement, achieving an IP64 waterproof rating.

Testing and Quality Control

All BNC-to-DC plug cable harnesses undergo thorough continuity, tensile strength, and airtightness testing.

- Resistance ≤ 50mΩ

- Tensile strength ≥ 30N

- Airtightness maintained at 50kPa

Quality control includes raw material inspection and durability testing (≥ 5000 plug-in/plug-out cycles).

This BNC male to DC plug cable harness, produced by Kaweei's custom wiring harness factory, features meticulous workmanship and comprehensive quality control, ensuring it is stable, durable, and meets customer needs. If you require a custom wiring harness, please contact us.