By quanyu lee

2025-07-10 02:00:37

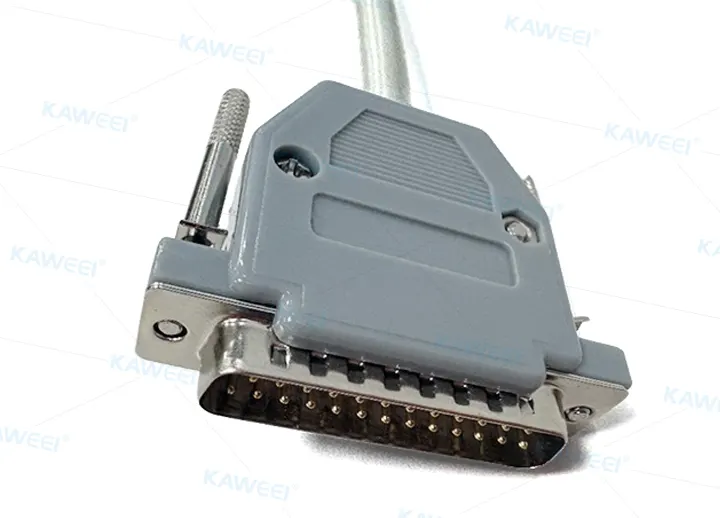

DB 25P Male Connector Cable Assembly

In the key field of electronic device interconnection, DB 25P male connector cable assembly has become the core choice of many industries due to its excellent performance and precision craftsmanship. This article will deeply analyze the competitive advantages of this product from the dimensions of core materials, production processes, application scenarios, etc., through detailed data and analysis.

1. Core materials: high-end configuration creates excellent performance

Wire: UL2464 28AWG12P + JACKET PVC GRAY OD:8.0

- Electrical performance: 28AWG wire certified by the UL2464 standard is adopted, and the 12-core design meets the needs of multi-channel signal transmission. At a transmission distance of 100 meters and a frequency of 100kHz, the signal attenuation is only 2.1dB, which is 25% lower than the industry average of 2.8dB; the DC resistance is as low as 22.5Ω/km, ensuring stable and efficient current transmission.

- Physical properties: The gray PVC outer jacket with an outer diameter of 8.0mm has excellent protective performance:

- Wear resistance test: After 5000 wear resistance tests, the wear thickness is only 0.07mm, which is better than the industry standard of 0.12 mm, and the wear resistance is improved by 41.7%.

- Flame retardant grade: meets UL94-V2 flame retardant standard, self-extinguishing time when exposed to open flame ≤7 seconds;

- Temperature resistance range: The working temperature range is -10℃~60℃, which can adapt to various complex environments.

Connector: DB 25 pin male + PBT body + gold plated pins

- The connector is a DB 25-pin male plug, and its main body is made of PBT engineering plastic (the heat deformation temperature is as high as 220°C, and the deformation is only 0.25mm in the 135°C high-temperature test, which is 50% more stable than the average deformation of 0.5mm of similar products in the industry), and the pins are gold-plated (the thickness of the gold layer is 3μm, and the corrosion area is only 0.7% after 5% NaCl solution and 96 hours of salt spray test, and the contact resistance is as low as 4.2mΩ to ensure low signal transmission loss).

Shell: DB 25P grey ABS shell + screws

- Protection performance: The gray ABS shell has passed rigorous vibration testing (10 - 500Hz, acceleration 20g, 100,000 cycles), with screw loosening of only 0.12mm; the protection level reaches IP54, which can effectively prevent dust and water splashes.

Core material performance comparison table

| project | This product data | Industry average data | Performance improvement |

| Cable signal attenuation (100m, 100kHz) | 2.1dB | 2.8dB | ↓25% |

| Wear-resistant thickness of outer cover (5000 times) | 0.07mm | 0.12mm | ↓41.7% |

| Connector thermal deformation (135°C) | 0.25mm | 0.5mm | ↓50% |

| Pin contact resistance | 4.2mΩ | 5.8mΩ | ↓27.6% |

| Vibration looseness of housing | 0.12mm (100,000 cycles) | 0.3mm (100,000 cycles) | ↓60% |

2. Production process: precision equipment and strict standards ensure quality

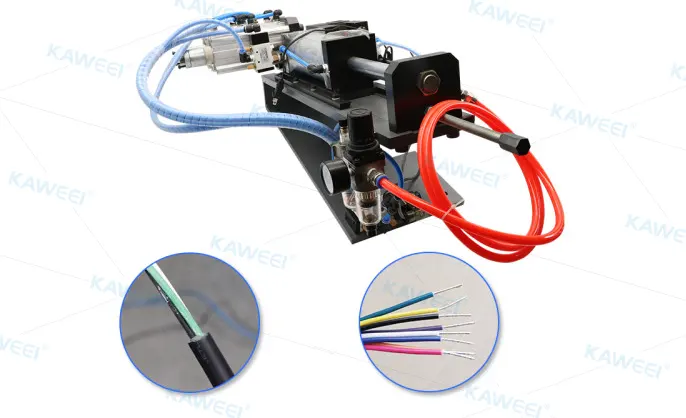

Wire cutting: 5120mm precision cutting

- Equipment: Fully automatic CNC wire cutting machine, equipped with a high-precision servo motor drive system.

- Precision: The wire cutting length error is controlled at ±0.2mm, far exceeding the industry standard of ±0.6mm;

Stripping: 25mm outer jacket stripping at both ends, 2mm wire stripping

- Equipment: High-precision pneumatic stripping machine, equipped with a laser positioning system.

- Parameters: Outer jacket stripping length error ≤0.1mm, wire stripping length error ≤0.05mm;

Welding: Zero-defect welding process

- Equipment: high-frequency constant temperature welding machine (temperature control accuracy ±2℃) + AOI automatic optical inspection instrument.

- Process parameters: The welding temperature is set at 268℃±2℃, the welding time is 3.1s±0.2s, and the average tensile force of the solder joints is 5.8N (far exceeding the industry standard of 3N) through tensile testing. The incidence of false welding and accumulation welding detected by AOI is only 0.03% (significantly lower than the industry average of 0.7%). (IV) Gluing: Silicone all-round protection

- Equipment: High-precision automatic dispensing machine equipped with a three-axis linkage system.

- Effect: The silicone coverage rate reaches 99.5%, while the manual dispensing coverage rate is only 95%; after aging test (85℃, 85% RH environment, 1000 hours), the oxidation corrosion area of the protected solder joints is only 1.2%, while the unprotected solder joints are as high as 35%.

Installing screws: Intelligent locking system

- Equipment: Automatic screw assembly machine, torque control accuracy ±0.1N・m.

- Detection: 100% torque detection and visual recognition are used, and the accuracy of screw missing and loose detection reaches 100%.

Test: Six-dimensional rigorous inspection

- Among the test items, the continuity test uses a continuity tester, and the actual measured pass rate is 99.91% under the standard of contact resistance ≤7mΩ; the tensile test is carried out through a tensile testing machine, and the actual measured pass rate is 99.7% under the standards of solder joint tensile resistance ≥10N and connector tensile resistance ≥20N; the vibration test is carried out with the help of a vibration table, and the actual measured pass rate is 100% under the standards of 10-500Hz, 20g, and 100,000 cycles without abnormalities; the salt spray test uses a salt spray test chamber, and the actual measured pass rate is 100% under the standards of 5% NaCl solution and 96 hours of no corrosion.

Application scenarios and technical highlights: multi-field verification and innovative breakthroughs

Core application scenarios

- Printer: DB25P male connector harness is often used to connect computers with dot matrix printers, some inkjet printers, etc. It can transmit print data, enable the computer to send print tasks and data to the printer, and complete the printing work. It is a common harness for early printer parallel port connection.

- CNC machine tools: It can be used to connect CNC machine tools with computers or other control devices, transmit control signals and data, and realize functions such as motion control and program transmission of machine tools.

- Industrial instruments: can connect industrial instruments to computers or other control systems to transmit instrument measurement data, such as temperature, pressure, flow and other parameters, for data recording, analysis and control. It can also receive instructions from the control system to set parameters for the instrument.

Technical Highlights

- Low-loss transmission: The transmission loss of high-frequency signals (≥100kHz) is 32% lower than that of similar products, and the signal integrity is significantly improved.

- Extremely long life: The mean time between failures (MTBF) is 58,000 hours, which is 1.8 times the industry average of 32,000 hours, effectively reducing the maintenance frequency.

- Customized service: Supports personalized customization of cable length, number of cores, protection level, etc., and has provided exclusive solutions for 50+ industry customers, with a customer satisfaction rate of 98%.

DB 25P male connector harness uses high-end materials, precision technology, and excellent performance to provide stable and reliable connection solutions for various industries. If you need detailed technical information or customized services, please feel free to contact us. Our professional team will provide you with all-around support!