By quanyu lee

2025-04-06 02:15:04

Guidelines for High Voltage Wiring Harnesses

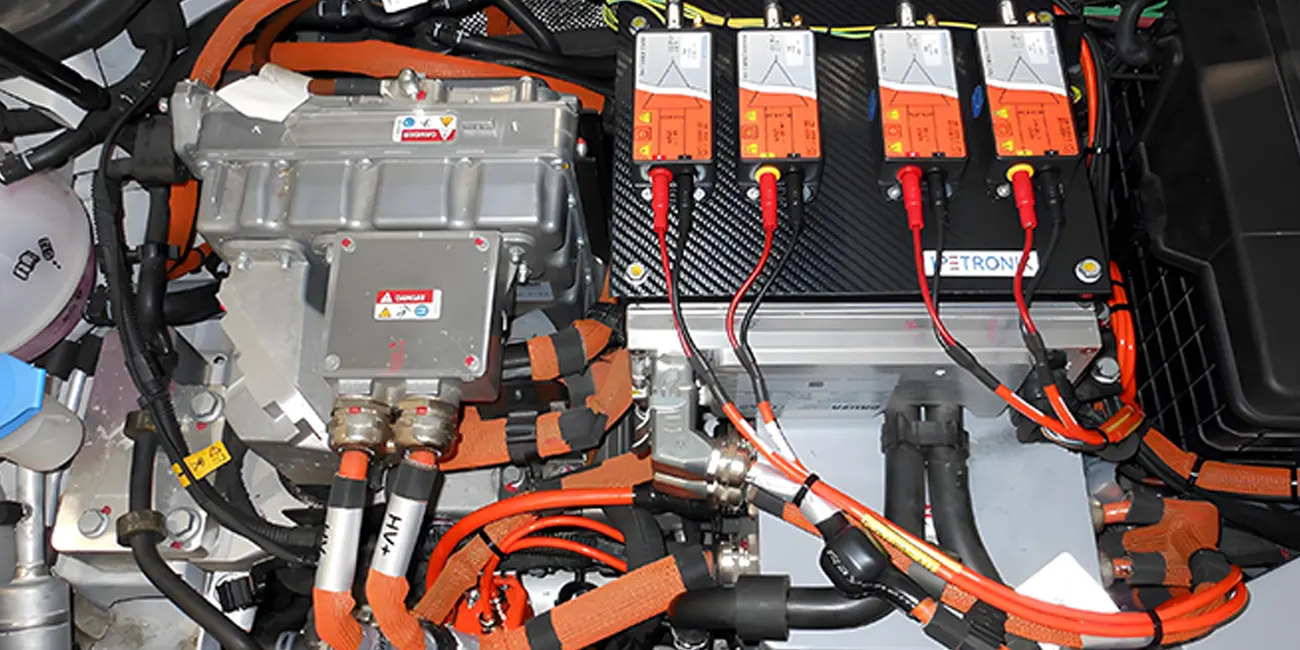

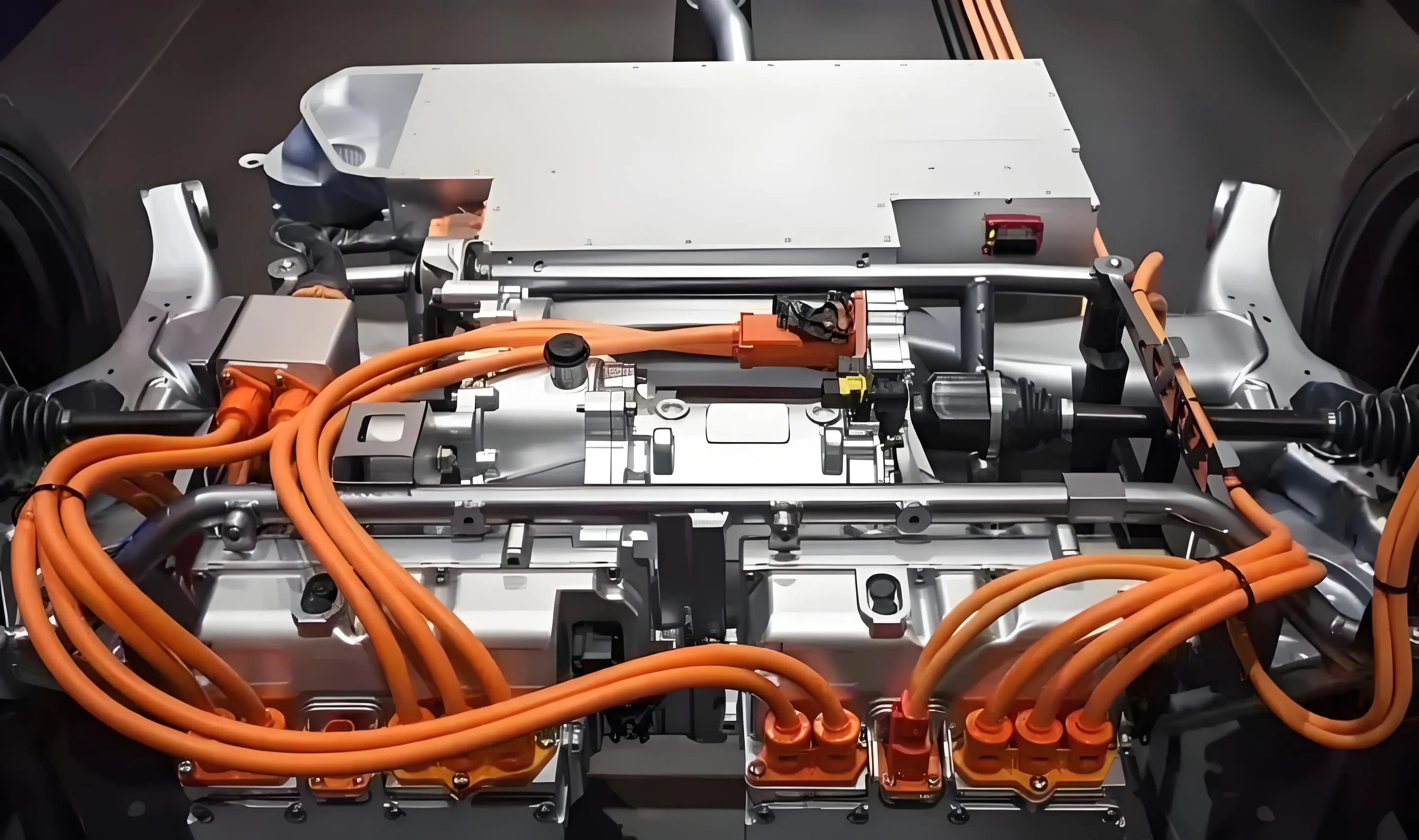

The high-voltage wiring harness of new energy vehicles is a power transmission carrier that connects key components such as high-voltage battery systems, drive motors, and charging devices. It is responsible for energy distribution, signal transmission, and electromagnetic shielding functions, and is regarded as the "neural network" of the high-voltage system of new energy vehicles. Its working voltage is usually above 300V (some models reach 600V), much higher than the low-voltage wiring harness of traditional fuel vehicles (12V/24V).

Main components and structure

- Connector: Ensure fast insertion and stable connection of high-voltage circuits, in compliance with LV series or USCAR industry safety standards

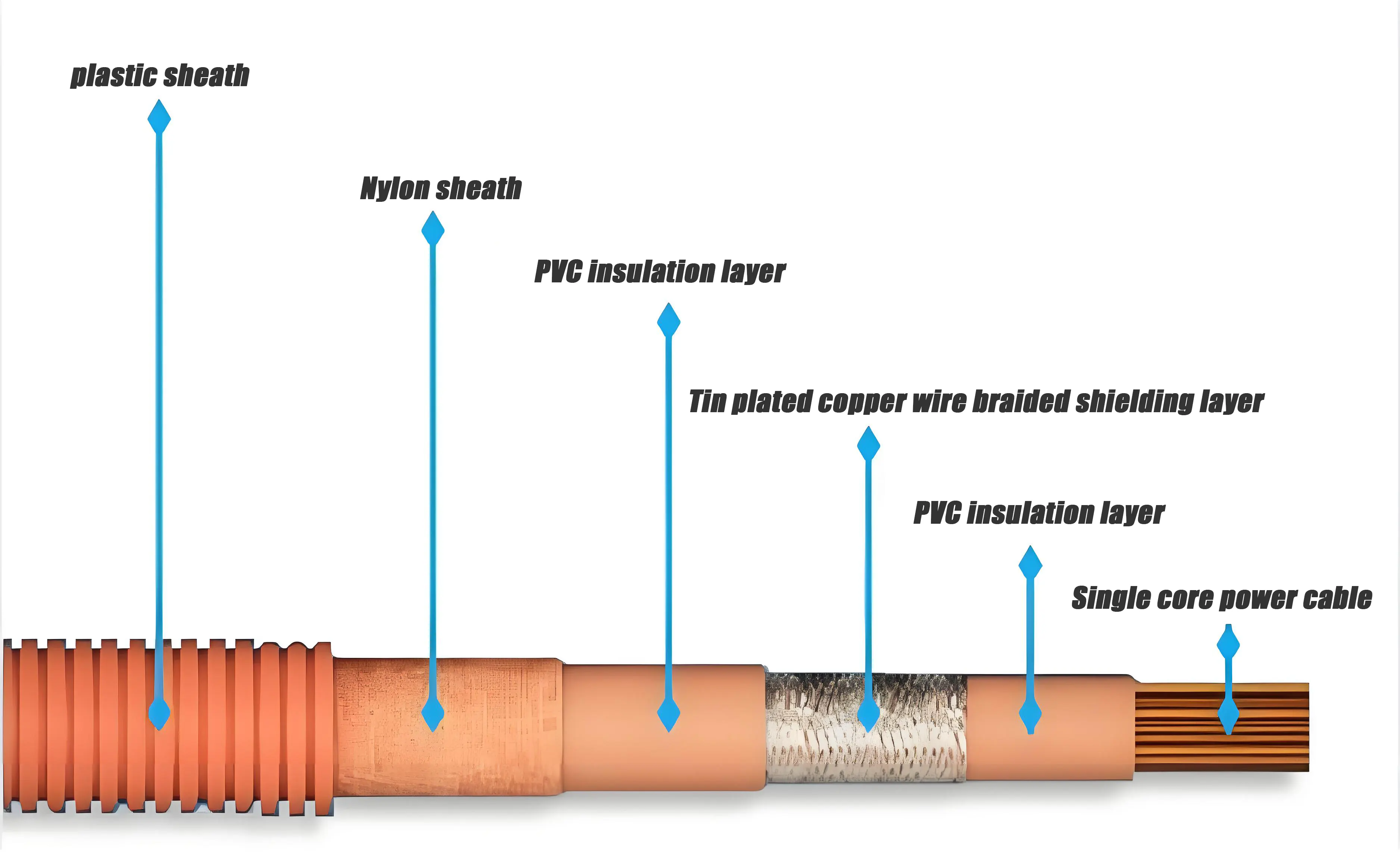

- Wire: Large section copper core cable (such as 2.5-95mm ²) is used, and the outer layer is wrapped with high insulation materials such as silicone and TPU

- Covering: including corrugated pipes, flame-retardant tape, etc., used for physical protection and high temperature resistance protection

- Shielding layer: wrapped in metal braided layer or aluminum foil to suppress electromagnetic interference

Classification and Application Scenarios

| type | connection path | Typical scenario |

| High voltage harness for power battery | Power battery ↔ High voltage distribution box | Main energy transmission channel, supporting high current |

| Fast charging/slow charging wire harness | charging port ↔ High voltage distribution box/car charger | Supports fast charging (DC) and slow charging (AC) |

| Motor controller wiring harness | High voltage distribution box ↔ motor controller | Energy regulation of drive motor |

| High voltage accessory wiring harness | High voltage distribution box ↔ DC/DC、 Air conditioning compressor, etc | Vehicle mounted equipment power supply and thermal energy management |

Selection and Design of High Voltage Connectors

The selection of high-voltage connectors is also an important consideration in the design process. High voltage connectors are mainly responsible for the connection and transmission of high voltage and high current, and play an important role in ensuring human safety. When selecting, it is necessary to consider functions such as high voltage resistance, protection level, loop interlock, and shielding.

High voltage harness shielding design

High voltage wiring harnesses also need to consider shielding design. Due to the strong electromagnetic interference generated by high-voltage wire harnesses when transmitting high voltage electricity, it is necessary to use wire with braided shielding mesh, and when selecting high-voltage connectors, try to choose connectors with shielding design to suppress the electromagnetic interference generated by high-voltage wire harnesses.

Sealing and Waterproof Design for High Voltage Lines

In order to improve the mechanical protection and dust-proof and waterproof performance of high-voltage wire harnesses, protective measures such as sealing rings are used between the connectors and at the positions where the connectors are connected to the cables to prevent water vapor and dust from entering, thereby ensuring a sealed environment for the connectors and avoiding safety issues such as short circuits, sparks, and leakage between contacts.

At present, most high-voltage wire harnesses are protected by wrapping materials, which mainly have the functions of anti-wear, noise reduction, radiation heat source isolation, and aesthetics. Generally, orange high-temperature resistant and flame-retardant corrugated tubes or orange high-temperature resistant and flame-retardant cloth sleeves are used for complete wrapping.

High voltage wiring harness ensures efficient operation and passenger safety of new energy vehicle power systems.