By quanyu lee

2025-10-22 15:16:08

Wire Harness Connector Insertion & Withdrawal Force Standard Guide

The plugging and extraction force standard for wiring harness connectors is a key indicator for measuring connector performance. The plugging and extraction force determines the balance between the connector's assembly convenience and electrical reliability. If the plugging and extraction force is too large, it will lead to assembly difficulties and terminal damage. If the plugging and extraction force is too small, it may cause poor contact, increased resistance, or signal loss. Therefore, formulating and following a unified plugging and extraction force test standard is the basis for ensuring the stable operation of the wiring harness system.

Definition and measurement principle of insertion and extraction force

- Insertion Force: The maximum force required to insert a terminal.

- Withdrawal Force: The minimum force required to remove a terminal.

Insertion and extraction force refers to the axial force required to be applied during the insertion and separation process of the connector. Insertion force reflects the resistance during docking. Excessive force will cause operational difficulties. Extraction force measures the retention force. Excessive force may cause poor contact. The core influencing factors include terminal material, contact pressure, surface treatment, and ambient temperature and humidity.

Measurement Principle

The insertion and extraction force test simulates manual insertion and extraction actions and records the force curve in real time. Peak force values are captured using sensors. For example, USB Type-C insertion force must be ≤30N, while automotive connector extraction force may require ≥80N.

- Number of cycles: Typically, 5,000-10,000 cycles are tested to verify performance degradation after long-term use.

- Standard method: Control the insertion and extraction speed and frequency according to international standards or industry specifications to ensure data accuracy.

Common international and industry plugging force standards

- Reference for electronic connector insertion and extraction force test method: IEC 60512-13-2

- Reference for pluggable performance requirements for signals, controls, and power supplies: UL 1977

- Reference for plug-in specifications of vehicle electrical connectors: ISO 8092-2

- Japanese automotive industry connector performance standard reference: JASO D616

These standards ensure that wiring harness connectors from different manufacturers are consistent and compatible in terms of plugging and unplugging performance.

Reference range of wiring harness connector insertion and extraction force

| Terminal specifications | Maximum insertion force (N) | Minimum extraction force (N) | Application areas |

| 0.64 mm | ≤35 | ≥5 | Automotive sensor wiring harness |

| 2.8 mm | ≤75 | ≥10 | Control and power wiring harness |

| 6.3 mm | ≤100 | ≥15 | Power transmission harness |

| Micro Fit | ≤20 | ≥3 | Communications and electronic equipment |

Wiring harness connector insertion and extraction force test method

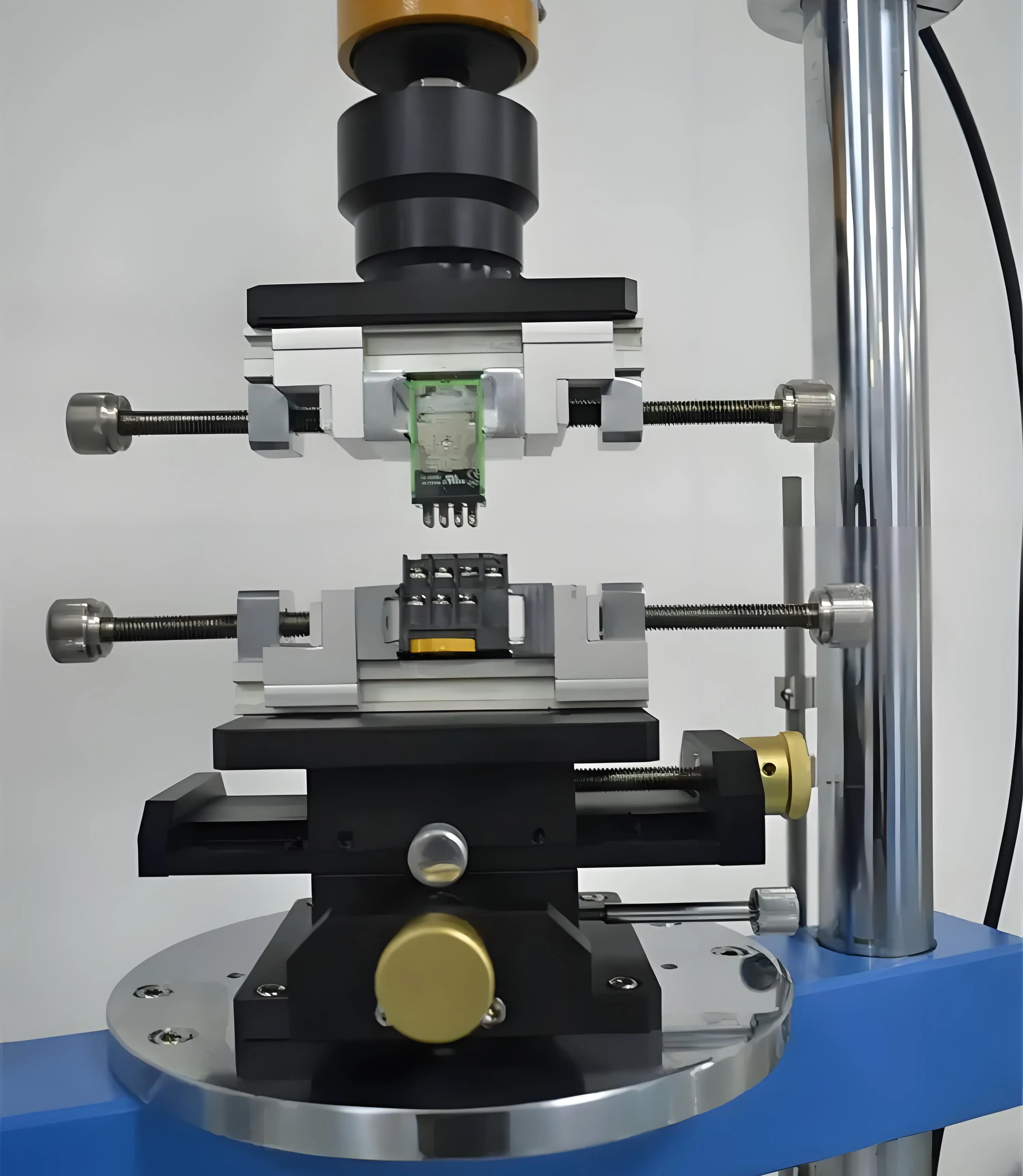

- Sample Preparation: Use standard terminals and wire harnesses to ensure assembly meets specifications.

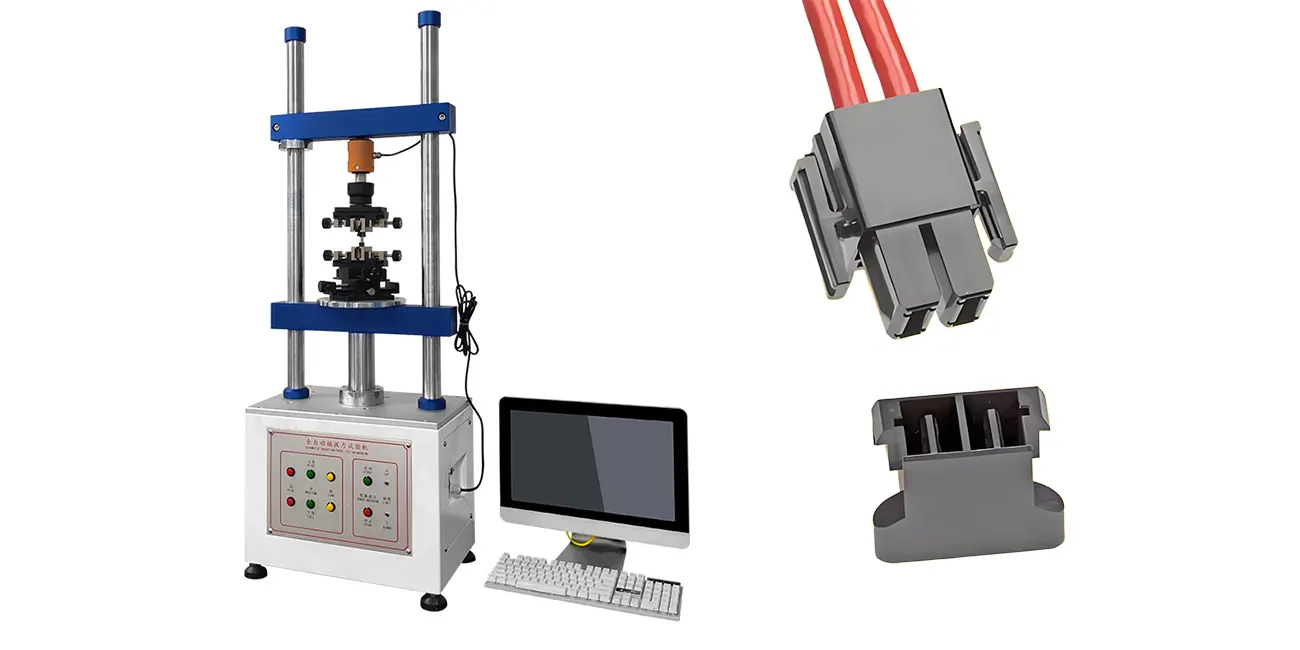

- Testing equipment: Use an insertion and extraction force tester (such as Imada or ZwickRoell).

- Test conditions: Insertion and removal directions maintained coaxially, test speed 50 mm/min, ambient temperature 25±5°C.

- Test frequency: ≥10 insertion/extraction cycles to evaluate terminal fatigue performance.

- Data Analysis: Record the maximum insertion force and minimum extraction force and compare them with the standard values.

Key factors affecting the plugging and unplugging force of wiring harness connectors

- Terminal spring design: The spring shape determines contact pressure and insertion force.

- Plating quality: Tin or gold plating affects the friction coefficient and conductivity.

- Molded case tolerance: Dimensional deviations can cause overtightening or undertightening.

- Environmental conditions: High temperature, humidity, and corrosive gases can reduce the extraction force.

- Assembly process: Crimp errors can cause terminal tilt or friction problems.

Frequently Asked Questions (FAQ)

Q1: What happens if the insertion force is too high?

Excessive insertion force may damage terminals or housings. Check spring design, surface treatment, and tolerance levels.

Q2: What does a low withdrawal force indicate?

A low withdrawal force typically indicates insufficient contact pressure, which can lead to unstable electrical signals.

Q3: Does Wire Harness Assembly provide connector testing services?

Yes. WIRE HARNESS ASSEMBLY offers UL and ISO-certified wire harness customization, including insertion force testing, terminal matching, and reliability validation.

WIRE HARNESS ASSEMBLY specializes in high-quality wire harness customization and supports small quantities and diverse products. If you need a customized wire harness, please don't hesitate to contact us.