By quanyu lee

2025-04-11 01:22:44

Elevator Wiring Harness Guide: A System Overview from Safety and Structure to Installation

In modern buildings, elevators have become an essential mode of transportation, and elevator wiring harnesses are a crucial component supporting their stable operation. Like a neural network, they transmit power, control signals, and safety information to every part of the elevator system. Many elevator malfunctions, such as door operators not working, buttons failing, or abnormal floor displays, can often be traced back to wiring harness issues. To better understand the safe operation mechanism of elevators, it is necessary to provide a systematic and easy-to-understand explanation of elevator wiring harnesses.

1. What is an elevator wiring harness?

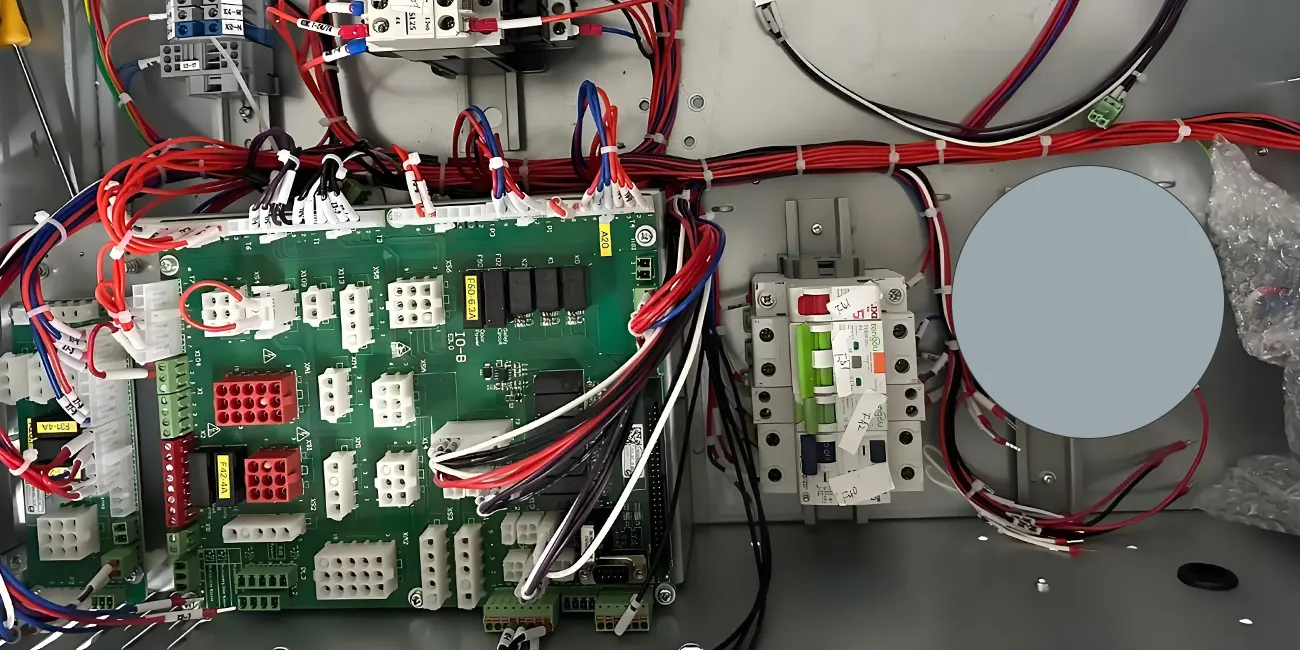

An elevator wiring harness is a group of electrical components consisting of various wires, connectors, sheathing materials, and fixing structures. It is distributed throughout the hoistway, car, door operators, and control cabinet, used to achieve power connections and signal transmission for the elevator.

In an elevator system, the most representative part is the traveling cable, which bends continuously as the car moves up and down. A single traveling cable can be tens of meters long and withstand hundreds or even thousands of bending actions daily. In addition, there are door operator wiring harnesses, car interior wiring harnesses, and control cabinet wiring harnesses, which together form a highly coordinated electrical network.

Elevator wiring harnesses are special because they must operate for extended periods in dynamic, vibration-induced, humidity-changing, and electromagnetic interference environments, while also meeting high safety and high reliability requirements.

2. Operating Characteristics of Elevator Wiring Harnesses

Unlike ordinary industrial wiring harnesses, elevator wiring harnesses operate in a highly dynamic environment. The traveling cable is constantly bent during the car's ascent and descent, while the door operator wiring harness endures frequent pulling and vibration during door opening and closing. High humidity, dust, and potential temperature fluctuations in the hoistway all accelerate the aging of the wiring harnesses.

The elevator control system also has extremely stringent requirements for signal quality. Interference with the signal lines can lead to incorrect floor displays, unstable speed control, or even elevator stoppage. Therefore, shielding structures, flexible conductors, and wear-resistant sheaths are essential components in the design of elevator wiring harnesses.

3. Common Problems with Elevator Wiring Harnesses

Elevator wiring harnesses may experience various problems during long-term use; some of the more common ones include:

- Bending fatigue: Repeated bending of the traveling cable may cause the internal copper wires to gradually break, leading to signal instability or complete interruption.

- Sheath aging: The shaft environment can cause wear and cracking of the sheath, affecting insulation performance.

- Loose connectors: Long-term vibration can cause connectors to loosen, potentially leading to malfunctions in the door operator, buttons, or display screen.

- Electromagnetic interference: High-frequency interference from the inverter can affect control signals; if the wiring harness lacks shielding, malfunctions are likely to occur.

These malfunctions not only affect the comfort of riding the elevator, but may also cause safety hazards such as elevator shutdown.

4. How to Choose a Reliable Elevator Wiring Harness?

To ensure the long-term stable operation of elevators, the selection of wiring harnesses requires careful consideration of materials, structure, and compatibility.

In the traveling cable section, the flexible conductor is crucial. Highly flexible multi-strand copper wire can withstand repeated bending better than ordinary single-strand copper wire. Simultaneously, the wiring harness sheath material should be selected based on the operating environment, such as:

- Low Smoke Halogen-Free Material (LSZH)

- Abrasion-Resistant TPU Sheath

- Special Modified PVC

These materials produce less smoke during a fire and can withstand friction and impacts within the shaft.

When making a selection, the following standards should be prioritized:

EN 81-20 / EN 81-50 Elevator Safety Standards:

These are standards commonly followed by elevator manufacturers in Europe and America.

The control system must have a good shielding design to resist frequency conversion interference, the traveling cable must have a tensile core to prevent copper wire from being stretched and damaged, and the connectors must be shock-resistant, plug-and-pull-resistant to prevent loosening, so as to ensure signal stability and accurate control.

5. Key Points for Installation and Maintenance

Even the best cable harnesses will have a significantly shortened lifespan if installed improperly. During installation, avoid twisting, knotting, or forced bending of cables; all bending radii must be within safe limits. Simultaneously, the mounting positions of the accompanying cables must be properly designed to distribute weight evenly and avoid localized pressure.

Regarding maintenance, it is essential to regularly inspect the surface of the cable harness, connectors, and moving parts for wear. Especially in buildings with frequent elevator use, any minor cracks or signal anomalies should be addressed promptly to prevent greater safety hazards.

6. Professional wire harness factory

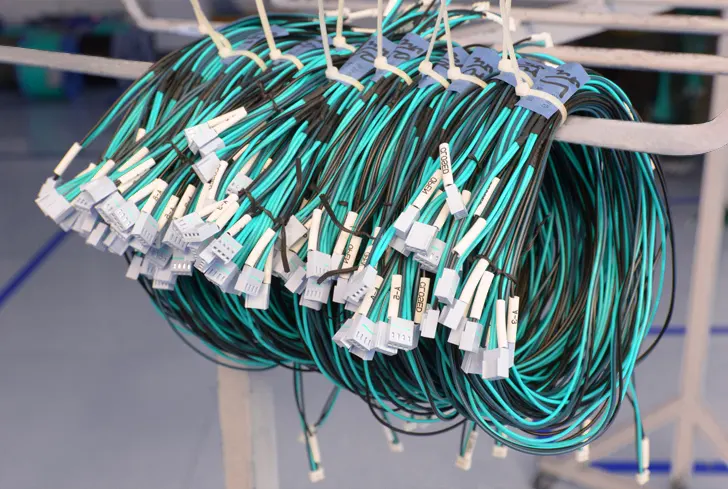

For engineering companies or elevator manufacturers, if they need to customize high-flexibility traveling cables, special interface harnesses, door operator shielded harnesses, etc., in bulk, they can cooperate with professional suppliers, such as WIRE HARNESS ASSEMBLY (a harness customization factory):

The factory can provide customized wiring harness solutions that meet UL/IEC standards and support small-batch trial production and structural optimization, which is especially helpful for the retrofitting of non-standard elevators.

FAQ: Frequently Asked Questions

How long do elevator wiring harnesses typically last?

The lifespan of a wiring harness depends on usage frequency, installation quality, and the shaft environment. Generally, it can last 5-10 years. For elevators used frequently, it is recommended to have them inspected sooner.

Why are elevator traveling cables more prone to failure?

Because they experience thousands of bends daily, coupled with the effects of gravity, they are the most heavily loaded part of the entire elevator wiring harness.

Can ordinary industrial cables replace elevator wiring harnesses?

No. Elevator wiring harnesses require greater flexibility, bending resistance, and flame-retardant properties, which industrial cables cannot provide.

How to determine if a wiring harness needs replacement?

If you notice signal fluctuations, sheath cracks, broken wires, or loose connections, replacement should be arranged immediately.

Conclusion

Although elevator wiring harnesses may seem ordinary, they are core "invisible components" ensuring the safe operation of elevators. A thorough understanding of their structure and operating characteristics can help designers, installers, and maintenance personnel plan and manage elevator systems more effectively. Through proper selection, standardized installation, and regular maintenance, elevator wiring harnesses can maintain long-term stability in complex environments, providing safety assurance for daily traffic.