By quanyu lee

2025-04-01 09:27:10

Aerospace Wire Harness: Essential Guide

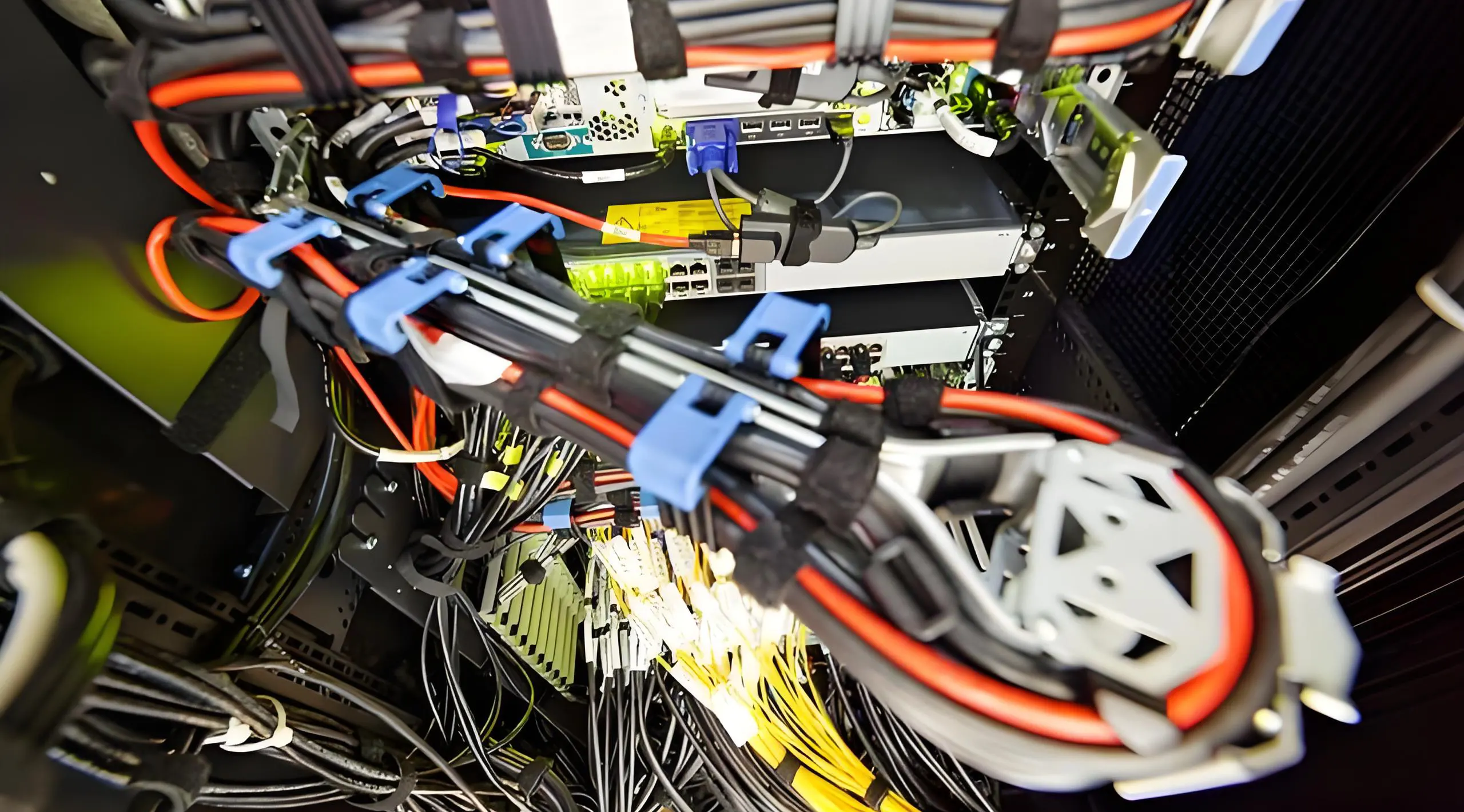

Aerospace wire harness is a critical component used in aircraft, spacecraft, and related systems to transmit power and signals. It ensures stable communication between onboard systems, improves reliability, and withstands extreme environmental conditions such as high vibration, temperature fluctuations, and electromagnetic interference.

What Is an Aerospace Wire Harness?

An aerospace wire harness is a structured assembly of wires, cables, and connectors bundled together to organize and protect electrical circuits. Unlike standard wiring systems, aerospace harnesses must meet strict industry standards, such as AS9100 and MIL-Spec, to ensure safety and performance in mission-critical applications.

Key features include:

- Lightweight, durable materials

- Resistant to heat, cold, moisture, and chemicals

- Optimized wiring saves space and reduces weight

Aerospace Wire Harness vs. Standard Wire Harness

While a regular wire harness is used in automotive or industrial settings, an aerospace wire harness is engineered for extreme conditions. The difference lies in:

- Material selection — aerospace uses Teflon, Kapton, or PTFE-insulated wires for high temperature resistance.

- Manufacturing precision — aerospace harnesses require 100% continuity testing and often use laser wire marking for traceability.

- Environmental protection — additional shielding for electromagnetic interference (EMI) and radio frequency interference (RFI).

Manufacturing Process of Aerospace Wire Harness

The production of an aerospace wire harness involves:

-

Design and engineering — custom layouts to meet space and weight constraints

-

Wire cutting and stripping — precision tools to avoid insulation damage

-

Terminal crimping and soldering — ensuring strong and reliable connections

-

Assembly and bundling — using lacing tape or heat shrink tubing for protection

-

Testing and inspection — continuity, insulation resistance, and environmental stress testing

Choosing a Reliable Aerospace Wire Harness Supplier

When sourcing an aerospace wire harness, look for:

- Certifications — AS9100, ISO 9001, and MIL-Spec compliance

- Customization capability — ability to produce harnesses tailored to your specifications

- Quality assurance — rigorous testing protocols to ensure reliability

Applications of Aerospace Wire Harness

Aerospace wire harnesses are used in a wide range of aviation and space-related systems, ensuring reliable electrical connections in critical operations. Common application fields include:

-

Commercial Aircraft – Wiring harnesses are used in flight control systems, communication equipment, lighting, and cabin entertainment systems.

-

Military Aircraft – Integrated into radar systems, weapon control systems, navigation equipment, and mission-critical avionics.

-

Spacecraft & Satellites – Essential for data transmission, power distribution, and control signals in satellites, space stations, and exploration probes.

-

Unmanned Aerial Vehicles (UAVs) – Provide lightweight and durable connections for cameras, sensors, GPS modules, and control units.

-

Helicopters – Support navigation, engine monitoring, avionics, and emergency communication systems.

-

Ground Support Equipment – Used in diagnostic tools, maintenance platforms, and power supply systems for aircraft and spacecraft.

By tailoring aerospace wire harness designs for each application, manufacturers ensure high reliability, optimal performance, and compliance with strict aerospace industry standards.

Aerospace wire harnesses are an indispensable electrical connection system in aerospace vehicles. They are responsible for transmitting power and signals in complex environments to ensure the safe and stable operation of the aircraft.