By quanyu lee

2025-05-19 01:59:11

New Energy Vehicle Lightweight Wiring Harness Guide

Lightweight wiring harnesses for new energy vehicles reduce the weight and volume of wiring harnesses while ensuring safety and electrical performance through material innovation and structural simplification, thereby helping new energy vehicles minimize weight.

Ultra-fine wire application

New energy vehicle wiring harnesses use wires with a cross-sectional area of only 0.13mm² (containing 7 copper wires as thin as hair), which is 20% lighter than traditional wiring harnesses, while also improving stability and high temperature resistance.

The strength of thin-wire conductors can be improved by using copper-iron alloy, copper-tin alloy, or adding steel wire or carbon fiber filling to the conductors. Using high-strength metallocene polyethylene instead of polyvinyl chloride as the insulating layer can further increase the 0.13 mm2 thin wire. Ultimately, while ensuring electrical performance, the 0.13 mm2 thin wire can reach the strength of a 0.35 mm2 signal line.

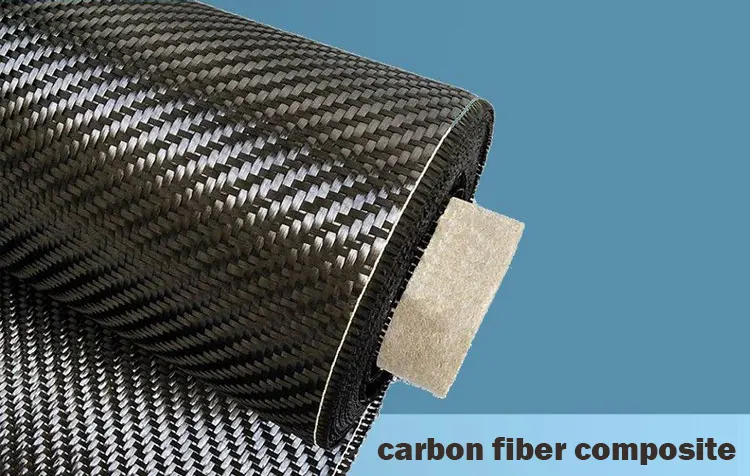

Aluminum and carbon fiber replacement

Aluminum wires gradually replace copper wires to achieve lightweight, and carbon fiber composite sheaths and thin-wall insulation technology further reduce the weight of wiring harnesses, helping to reduce the weight of the entire vehicle by 10%-15%.

Tesla recently performed a "slimming operation" on the Model 3: the messy wires in the car were reduced from 5 kilometers to 1.5 kilometers, just like a bunch of messy wires were straightened into a headphone wire.

There are three benefits to doing this:

- Lighter cars: For every 10% reduction in the weight of the wires, the weight of the entire vehicle can be reduced by 3%, and the cruising range can be increased by 25-40 kilometers (if it can reach 500 kilometers).

- More economical and environmentally friendly: The use of lightweight materials such as aluminum + new processes can reduce the cost of each piece of wood by 15%-20%, and carbon emissions during production and use will also be reduced.

- Better performance: Although the wires have become lighter, they can still withstand the 1500V voltage required by the 800V high-voltage system by improving the insulation material and aluminum alloy design (such as using liquid-cooled high-voltage wires).

To put it simply, the lightweighting of the drive harness of new energy vehicles means making the wires in the car lighter and thinner, but with better performance. This is not only the focus of the technical competition among car companies, but also helps us achieve environmental protection goals (dual carbon) and promote the upgrading and progress of the entire automotive industry. Simply put: use fewer materials to make better products, which saves money and is environmentally friendly.