By quanyu lee

2025-04-06 01:40:48

Spring Cable Guide: Structural Principles, Application Scenarios, and Customization Considerations

In modern industrial, medical equipment, communication systems, and automotive applications, the flexibility and reliability of connections have become core design considerations. Traditional straight cables often face problems such as wear, tangling, and insufficient space in moving or rotating equipment, while the emergence of spring cables provides an ideal solution to this challenge.

This seemingly simple "spiral cable" actually integrates sophisticated mechanical design and materials science. It enables repeated expansion and contraction connections within a limited space while maintaining signal stability and structural integrity.

This article will provide a comprehensive analysis of the key technical aspects of spring cables, from structural design and material selection to application examples and customization recommendations, helping you make more professional choices in practical engineering projects.

1. What is a spring cable?

A spring cable (also known as a spiral cable, coiled cable, or spiral cord) is a type of flexible cable that can stretch freely, its most distinctive feature being its spiral shape. Unlike ordinary cables, it can be repeatedly stretched and rebounded in dynamic environments without causing fatigue damage to the conductor or sheath.

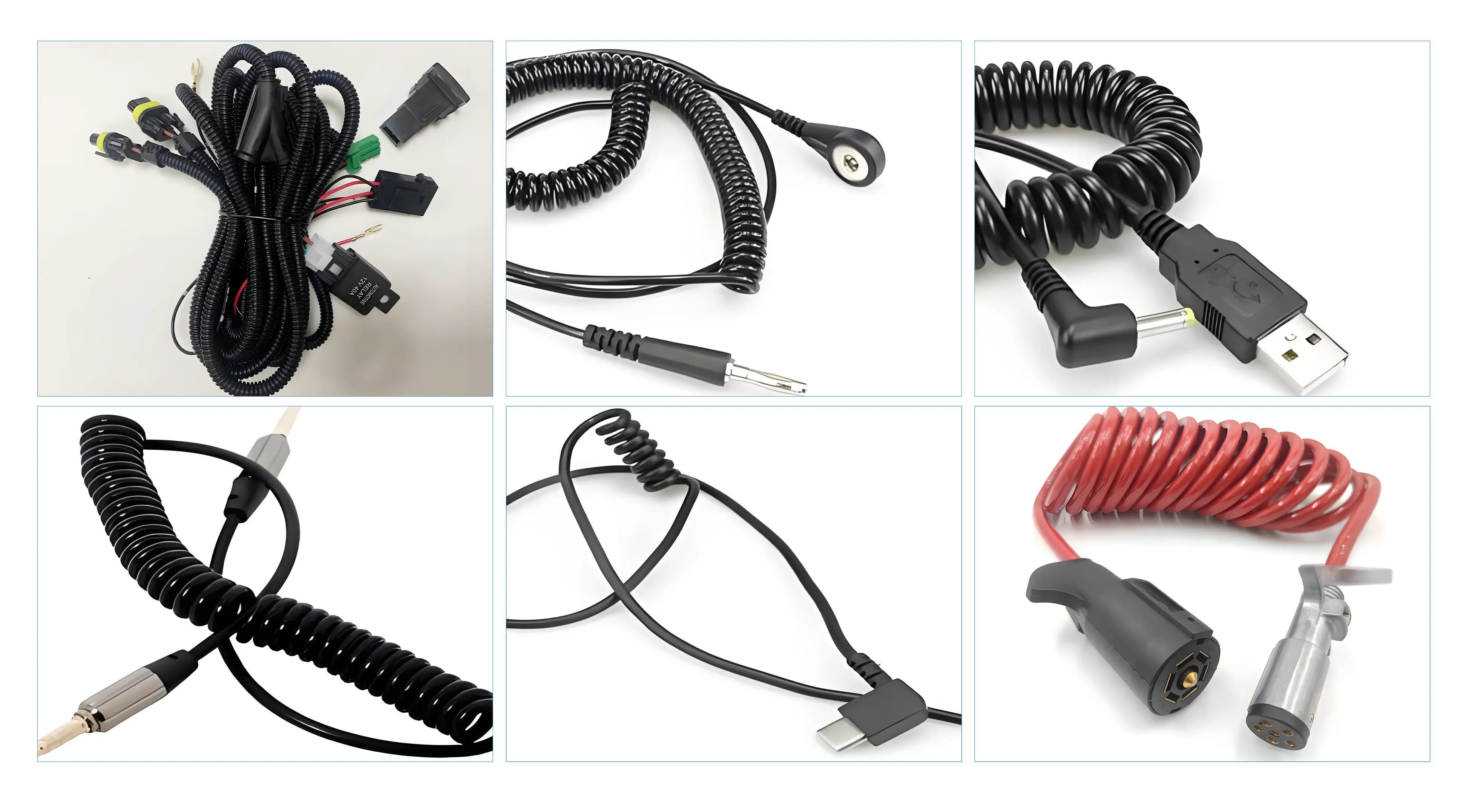

Common applications include industrial robotic arms, medical testing equipment, communication terminals, and charging systems. For example, probe cables in hospital monitors, interface cables in automotive diagnostic tools, and dynamic power supply cables in industrial robots are typical applications of spring cables.

2. Core Structure and Design Principles of Spring Cables

From its internal structure, the scientific nature of the spring cable far exceeds what one might imagine from its appearance:

1. Conductor layer: Utilizes multi-strand fine copper wire to ensure excellent flexibility and tensile strength.

High-end versions often use tin-plated or silver-plated copper wire to prevent oxidation and maintain signal stability.

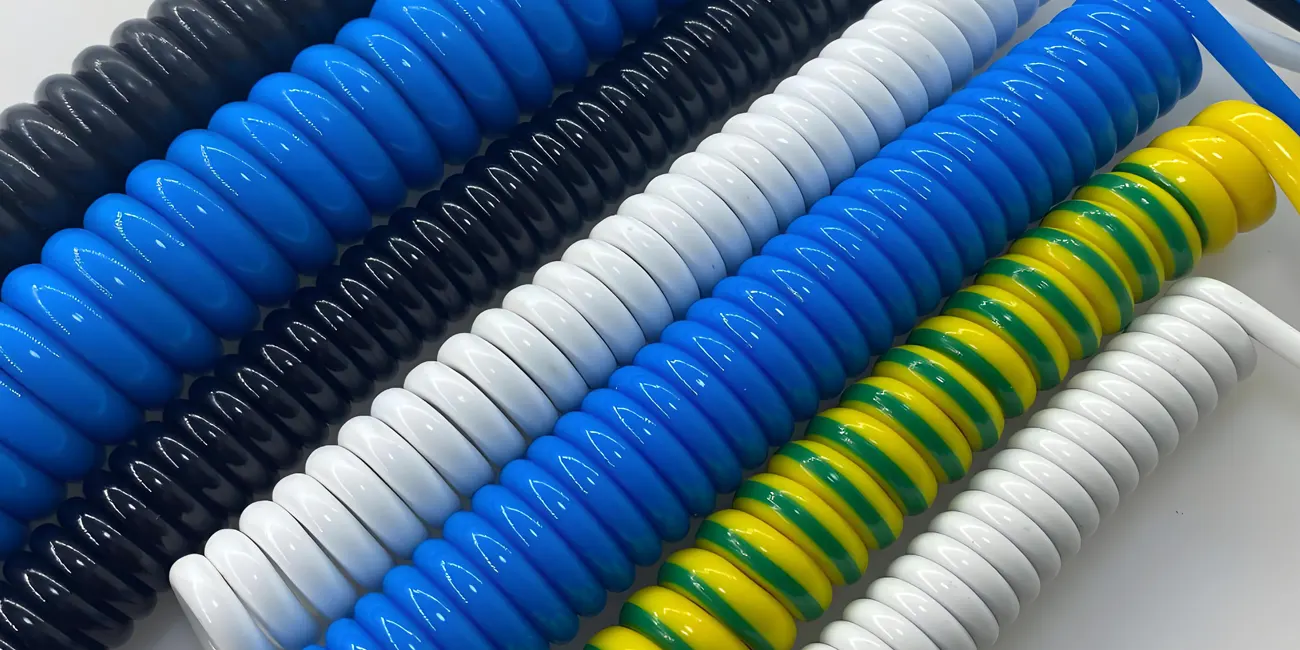

2. Insulation Layer: Depending on the application, materials such as PVC, PUR, TPU, or TPEE can be selected.

PUR exhibits excellent abrasion and oil resistance, while TPU offers superior low-temperature performance.

3. Coiling Process: The formation of the spring shape depends on a precise heating, winding, and tempering process.

The winding diameter, pitch, and tension control directly affect the rebound speed and lifespan.

4. Jacket & Elasticity: The sheath is both a protective layer and an "elastic memory."

It determines the cable's ability to recover from deformation after expansion and contraction. High-quality spring cables can withstand more than 100,000 expansion and contraction cycles without damaging the conductor.

3. Main Application Areas of Spring Cables

| Application scenarios | Functional requirements | Features |

| Industrial automation | Dynamic signal and power transmission | High elasticity, oil resistance, and bending resistance |

| Medical equipment | Human safety and flexibility | Low toxicity, odorless, easy to disinfect, and fatigue-resistant. |

| Communication and audio equipment | Portability and aesthetics | Anti-tangling and lightweight |

| New energy and vehicle systems | Dynamic power supply | Cold-resistant, heat-resistant, and UV-resistant |

For example, in the charging interface of new energy vehicles, the spring cable can be automatically retracted to reduce pulling and wear; in medical equipment, it can extend and retract with the movement of the equipment to improve safety and comfort.

4. Key Parameters When Customizing Spring Cables

When customizing or purchasing spring cables, the following technical parameters should be given special attention:

1. The extension ratio is usually controlled between 1:3 and 1:5.

Too high or too low a ratio will affect the lifespan and user experience.

2. Conductor cross-sectional area and wire diameter

It directly determines the current carrying capacity and signal quality.

3. Winding diameter and pitch

It affects rebound performance and space compression ratio.

4. Sheath material

Different materials are suitable for different environments (PUR is suitable for high-strength industrial applications, TPU is suitable for cold or outdoor environments).

5. Working environment

Temperature range, humidity, oil contamination, UV exposure, and bending radius are all key factors affecting lifespan.

5. Differences between spring cables and ordinary wire harnesses

Spring cables are a type of dynamic wire harness that differs significantly from traditional wire harnesses:

| Project | Ordinary wiring harness | Spring cable |

| Appearance | Linear structure | Spiral expansion |

| Space occupied | Larger | Compressible storage |

| Service life | It is relatively long when static and easily broken when dynamic. | Higher dynamic life |

| Typical applications | Fixed connection | Telescopic connection, mobility system |

In automated equipment, spring cables are often used in conjunction with custom wiring harness systems.

For example, WIRE HARNESS ASSEMBLY offers custom services that integrate spring cables with connectors, sheaths, and terminals into a complete solution, ensuring greater consistency and reliability.

6. Common Mistakes and Improvement Suggestions

- Ignoring Material Compatibility: Low-priced PVC is prone to brittleness at low temperatures; PUR or TPU should be selected based on the environment.

- Untested Rebound Life: Qualified products should pass at least 100,000 expansion and contraction cycles.

- Inappropriate Winding Parameters: Too dense a pitch will reduce elasticity, while too sparse a pitch will affect storage efficiency. The design should be optimized according to the space to be used.

7. How to Choose a Reliable Spring Cable Supplier

A high-quality supplier not only provides qualified products but also offers technical support during the design phase.

We recommend paying attention to the following points:

- Does it have ISO 9001, UL/CSA, or other certifications?

- Does it support small-batch or prototype production?

- Does it provide fatigue testing and inspection reports?

- Does it have independent wire harness assembly and terminal crimping capabilities?

- Can it recommend suitable materials and winding parameters based on environmental requirements?

Professional manufacturers such as WIRE HARNESS ASSEMBLY offer one-stop services from structural design and wire harness assembly to final molding, helping companies efficiently match spring cables with complete machines.

🧩 FAQ: Frequently Asked Questions about Spring Cables

1. What is the typical service life of a spring cable?

High-quality spring cables can typically withstand 100,000 to 500,000 expansion and contraction cycles. The lifespan mainly depends on the conductor flexibility, winding process, and sheath material. Using PUR or TPU sheaths and performing proper tempering and shaping can significantly extend the lifespan.

2. What is the biggest difference between spring cables and regular cables?

Regular cables are suitable for fixed wiring, while spring cables are designed for dynamic connections, allowing for repeated stretching and rebound without tangling. Their spiral structure effectively saves space and prevents stress concentration, making them ideal for mobile or rotating equipment.

3. Can spring cables be used in industrial robots or automated equipment?

Yes. Industrial-grade spring cables are commonly used in dynamic components such as robot arms, sensors, and control systems. It is recommended to choose oil-resistant, bend-resistant models that are UL/CSA certified to ensure stability and safety.

4. How to choose the material for spring cables?

- PVC: Economical, suitable for light load applications.

- PUR: Abrasion-resistant, oil-resistant, and tear-resistant, commonly used in industrial machinery.

- TPU/TPEE: Cold-resistant and quick-rebound, suitable for outdoor or medical applications.

- Silicone: Extremely flexible, suitable for medical and low-temperature environments.

Material selection should be based on a comprehensive evaluation of operating temperature, bending radius, and environmental medium.

5. Can the color and connectors of the spring cables be customized?

Of course. Professional manufacturers can customize colors, wire diameters, sheath materials, plug types, and overall lengths according to your needs.

Custom wire harness factories like WIRE HARNESS ASSEMBLY provide a one-stop solution from design and prototyping to mass production.

6. Do spring cables require maintenance?

Generally, no special maintenance is needed, but prolonged stretching to the maximum length should be avoided, and the sheath should be checked regularly for aging or hardening. For cables used outdoors, attention should be paid to UV protection and moisture protection.

7. What precautions should be taken when using spring cables in medical equipment?

Medical-grade spring cables must comply with environmental standards such as RoHS and REACH, and must use non-toxic insulation materials. Additionally, the cable surface should have antibacterial properties to ensure patient safety and equipment reliability.