By quanyu lee

2024-12-13 03:45:56

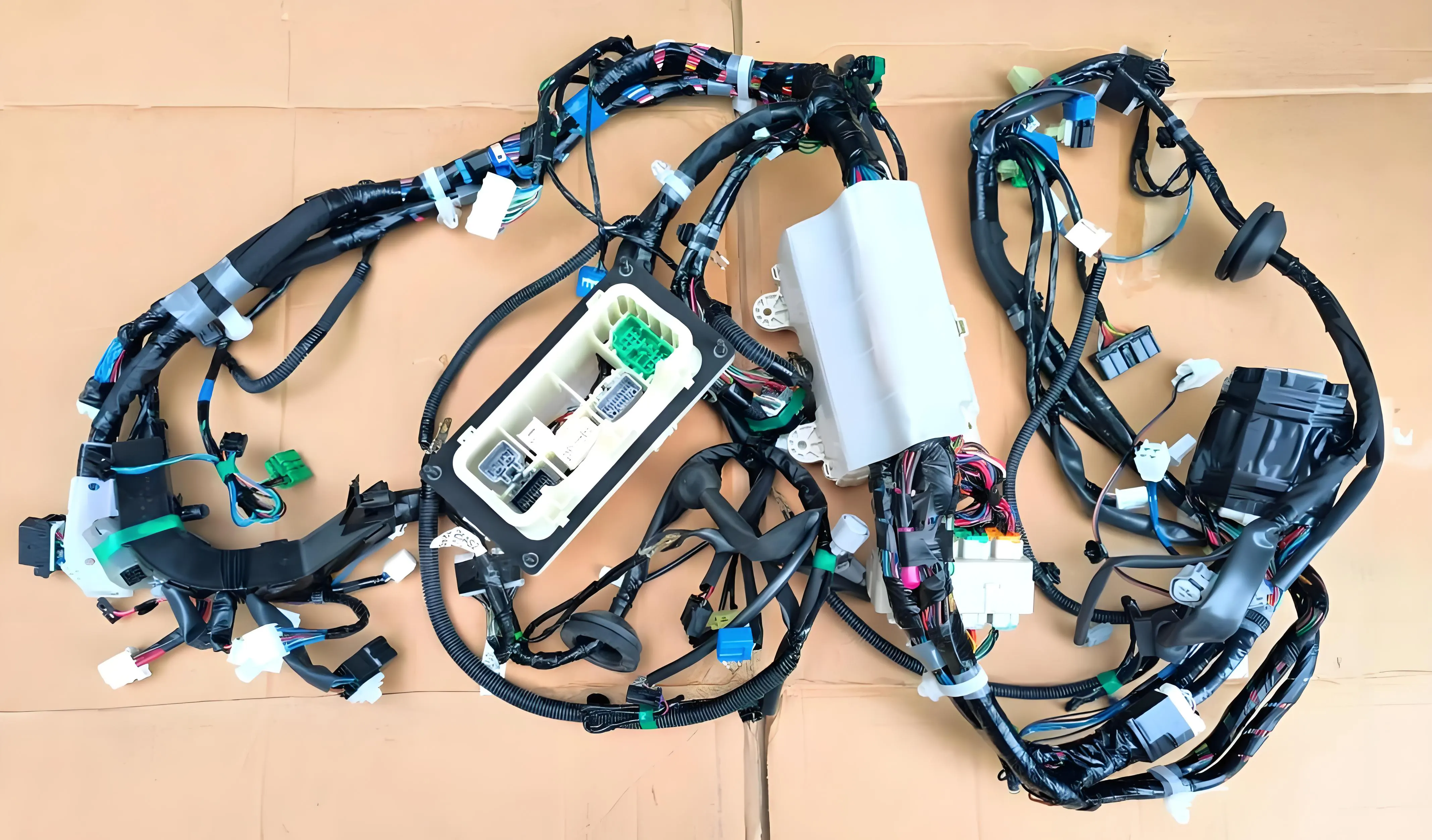

Automotive Engine Wiring Harness Guide

In modern vehicles, the engine wiring harness plays a crucial role in ensuring efficient communication between all electrical components. From ignition to fuel injection and sensor feedback, a well-designed harness keeps everything running smoothly. Without it, even the most powerful engine would fail to perform. Whether you’re replacing an old harness, upgrading for better performance, or customizing a vehicle, understanding the essentials of automotive engine wiring harnesses will help you make the right choice.

What Is an Automotive Engine Wiring Harness?

An automotive engine wiring harness is a structured bundle of wires, terminals, and connectors that transmit electrical power and signals throughout the vehicle. It connects the engine control unit (ECU), sensors, actuators, ignition system, alternator, and battery — enabling the engine to function efficiently.

Unlike loose wiring, an engine harness organizes and protects electrical circuits using insulated sleeves, flame-retardant over-molding, and durable connectors, reducing the risk of short circuits, vibrations, and moisture intrusion.

Key Functions

- Distributes electrical power from the battery to engine components.

- Transmits control signals between sensors and the ECU.

- Protects wires from heat, abrasion, and corrosion.

- Simplifies vehicle assembly and future maintenance.

Types of Automotive Wiring Harnesses

While the engine wiring harness is the heart of the vehicle’s electrical system, it works alongside other harness types to complete the entire network:

Harness Type |

Primary Function |

| Engine Harness | Controls engine sensors, fuel injectors, ignition coils, and alternator connections. |

| Main Harness | Connects dashboard instruments, ECU, and fuse boxes. |

| Battery Harness | Transfers power between the alternator, battery, and starter motor. |

| Body Harness | Manages lighting, air conditioning, and infotainment systems. |

| Door Harness | Controls power windows, locks, and mirrors. |

| Roof Harness | Integrates sunroof, lighting, and roof-mounted sensors. |

| Front and Rear Harnesses | Connects sensors, headlights, taillights, and auxiliary systems. |

Each harness must meet strict automotive standards for safety, heat resistance, and electrical performance.

OEM vs. Custom Engine Wiring Harness

When replacing or upgrading your wiring system, you’ll typically choose between OEM (Original Equipment Manufacturer) harnesses and custom-made or aftermarket harnesses. Both have distinct advantages depending on your vehicle type and project goals.

OEM Engine Wiring Harness

Advantages:

- Guaranteed fit and compatibility with the vehicle model.

- Meets or exceeds factory safety and performance standards.

- Ideal for vehicle restoration or factory-quality repair.

Disadvantages:

- Usually more expensive.

- Limited customization.

- May require dealership ordering and longer delivery times.

Custom or Aftermarket Harness

Advantages:

- Highly customizable for modified engines or performance setups.

- Often more affordable than OEM harnesses.

- Can improve durability and efficiency with upgraded materials.

Disadvantages:

- Quality can vary among manufacturers.

- Requires accurate specifications or professional installation.

When choosing a custom engine wiring harness, always verify the supplier’s engineering capabilities, certifications (e.g., ISO 9001, IATF 16949), and wiring diagram accuracy.

How to Select the Right Engine Harness

- Identify Vehicle Make, Model, and Year – Compatibility is key.

- Determine Harness Purpose – Replacement, upgrade, or performance tuning?

- Check Material Quality – Look for heat-resistant insulation and waterproof connectors.

- Review Electrical Specifications – Ensure proper wire gauge and connector ratings.

- Verify Warranty and Certification – Choose a manufacturer offering quality assurance and testing reports.

Manufacturers such as Kaweei and Wire Harness Assembly provide both OEM-style and custom wiring harness solutions that meet international automotive standards.

Troubleshooting Engine Wiring Harness Problems

A damaged engine harness can cause starting failures, misfires, or sensor malfunctions. Below is a simplified diagnostic process:

- Inspect Fuses and Relays – Replace blown fuses with identical ratings.

- Check Wire Insulation – Look for corrosion, burns, or brittle sections.

- Test Voltage Continuity – Use a multimeter to detect voltage drops or open circuits.

- Verify Ground Connections – Loose or corroded grounds are common fault points.

- Replace or Repair as Needed – Use factory-approved connectors and heat-shrink tubing for repairs.

If issues persist, a professional technician can perform advanced diagnostics using wiring diagrams and OBD-II scanners.

Replacing an Engine Wiring Harness: Step-by-Step Overview

- Document Everything – Photograph all connectors and routing paths before removal.

- Disconnect the Battery – Always start with the negative terminal.

- Remove Old Harness – Carefully detach connectors, clips, and brackets.

- Route New Harness – Follow original paths, avoiding heat zones or moving parts.

- Secure Connections – Use OEM-style clips and conduits for vibration protection.

- Test System – Reconnect the battery, start the engine, and verify electrical function.

Cost Considerations

The cost of repairing or replacing an automotive engine wiring harness can vary significantly:

- Minor repair: $50–$200

- Partial replacement: $300–$700

- Full engine harness replacement: $800–$1,500+

Custom harnesses for performance vehicles or complex systems can exceed these ranges. Always prioritize quality and safety over short-term savings.

Why Quality Matters

Using substandard materials or poorly crimped connectors can lead to voltage drops, engine stalling, or even electrical fires. A high-quality wiring harness ensures:

- Long-term reliability

- Resistance to heat, oil, and vibration

- Stable current flow and consistent performance

Whether you’re restoring a vintage car or building a high-performance engine, investing in a certified, well-engineered harness is crucial.

Conclusion

An automotive engine wiring harness is the backbone of your vehicle’s electrical system. Choosing the right harness — OEM or custom — ensures safe, efficient, and long-lasting operation. Always source from trusted manufacturers and follow professional installation practices to avoid electrical issues.

For custom or OEM automotive harness solutions, contact WIRE HARNESS ASSEMBLY— a specialized manufacturer offering reliable, certified, and fully customizable wiring systems for global automotive applications.

FAQ

Q1: How long does an engine wiring harness last?

A quality harness can last over 10 years, depending on environmental conditions, material quality, and maintenance.

Q2: Can I repair a damaged harness myself?

Yes, but only if you have proper tools and wiring diagrams. For complex repairs, professional service is recommended.

Q3: What materials are best for engine harness insulation?

Cross-linked polyethylene (XLPE) or PVC insulation provides heat and chemical resistance ideal for engine environments.

Q4: What are the signs of a bad engine wiring harness?

Engine misfires, warning lights, or non-responsive sensors may indicate corrosion, broken wires, or poor connections.